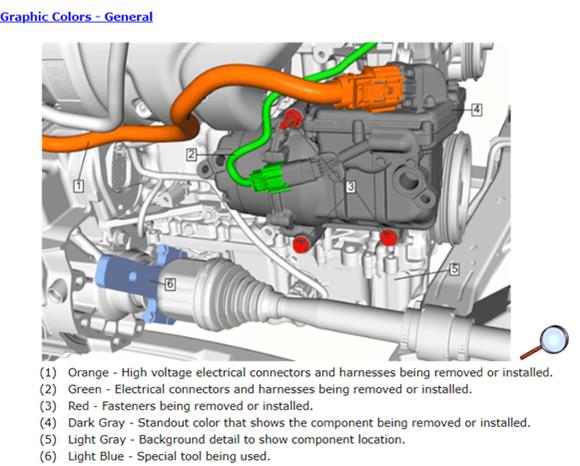

GM Graphic Colors & Symbols

These days many OEMs use colors in their graphics to describe repair procedures. They provide a simple universal description for procedures to follow when making repairs. Arrows and symbols are also used and provide additional repair or procedural instructions. Let’s take a quick look at some of these graphics from General Motors available in TruckSeries.

These days many OEMs use colors in their graphics to describe repair procedures. They provide a simple universal description for procedures to follow when making repairs. Arrows and symbols are also used and provide additional repair or procedural instructions. Let’s take a quick look at some of these graphics from General Motors available in TruckSeries.

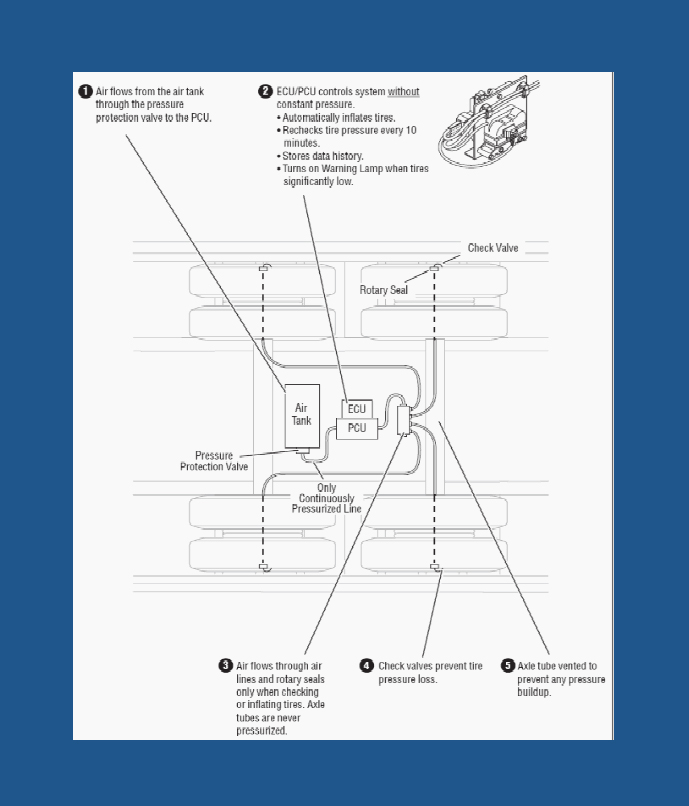

Driving down the road at some point all of us have noticed the large and small chunks of tire rubber on the country’s highway’s and byway’s. Most technicians know these road hazards can be attributed to Big-Rig trailer tires that have failed and separated; most like due to low tire pressure or improper re-treading. These faulty repairs can cause accidents due to swerving, and hundreds of thousands of dollars worldwide in property damage to vehicles and infrastructure.

Driving down the road at some point all of us have noticed the large and small chunks of tire rubber on the country’s highway’s and byway’s. Most technicians know these road hazards can be attributed to Big-Rig trailer tires that have failed and separated; most like due to low tire pressure or improper re-treading. These faulty repairs can cause accidents due to swerving, and hundreds of thousands of dollars worldwide in property damage to vehicles and infrastructure. It’s no surprise that there are many variations when it comes to truck maintenance schedules. The operating conditions for the individual vehicles or the fleet vehicles in general, help to determine what systems need to be serviced and when. In addition, the truck service information source will point out specific components that need to be checked, lubricated, cleaned, or replaced during those services. See how Mitchell 1’s TruckSeries can help you stay on top of those vital maintenances.

It’s no surprise that there are many variations when it comes to truck maintenance schedules. The operating conditions for the individual vehicles or the fleet vehicles in general, help to determine what systems need to be serviced and when. In addition, the truck service information source will point out specific components that need to be checked, lubricated, cleaned, or replaced during those services. See how Mitchell 1’s TruckSeries can help you stay on top of those vital maintenances. To be a Truck technician requires a lot of time and energy, and requires a major investment in your physical and mental being. Yet, as with every major investment everyone looks forward to a great return. To ensure the best chance at a great return, you must start with taking care of your best “tool”. You! Here are some great tips and tricks to help you get the best of you from our own Chris Wenberg.

To be a Truck technician requires a lot of time and energy, and requires a major investment in your physical and mental being. Yet, as with every major investment everyone looks forward to a great return. To ensure the best chance at a great return, you must start with taking care of your best “tool”. You! Here are some great tips and tricks to help you get the best of you from our own Chris Wenberg. When it comes to diagnosing and repairing electrical systems these days it can be tricky. At first glance everything appears to look good, so then why doesn’t it work? That’s where Mitchell 1’s

When it comes to diagnosing and repairing electrical systems these days it can be tricky. At first glance everything appears to look good, so then why doesn’t it work? That’s where Mitchell 1’s  A lot of what we diagnose these days involves a vehicle having symptoms and a DTC or a Diagnostic Trouble Code. However, occasionally a truck will come into a shop with symptoms and no DTC thus requiring the technician to pop open the hood and figure out what could be wrong. Mitchell 1’s

A lot of what we diagnose these days involves a vehicle having symptoms and a DTC or a Diagnostic Trouble Code. However, occasionally a truck will come into a shop with symptoms and no DTC thus requiring the technician to pop open the hood and figure out what could be wrong. Mitchell 1’s  Diagnostic procedures usually help us to dot our i’s and cross our t’s when we take the time to follow them. Having a diagnostic path to follow is a great help, even though it may appear a bit laborious at times. Here are 5 steps from our own Jake Schell to help you get a more accurate diagnosis.

Diagnostic procedures usually help us to dot our i’s and cross our t’s when we take the time to follow them. Having a diagnostic path to follow is a great help, even though it may appear a bit laborious at times. Here are 5 steps from our own Jake Schell to help you get a more accurate diagnosis. When it comes to protecting and restoring the environment, it should come as no surprise that the commercial trucking industry would adopt positions that mirror those of the public sector. As a result, in recent years, several large commercial truck manufacturers have been studying the possibilities and logistics of using fully-electric commercial trucks, typically known as EV’s (Electric Vehicles). Read more about it here.

When it comes to protecting and restoring the environment, it should come as no surprise that the commercial trucking industry would adopt positions that mirror those of the public sector. As a result, in recent years, several large commercial truck manufacturers have been studying the possibilities and logistics of using fully-electric commercial trucks, typically known as EV’s (Electric Vehicles). Read more about it here. Most of us have been on the customer side reading those fateful words for something where we know a problem exists. The frustration increases to monumental proportions when the problem is a blaring fault code indicator light on the instrument panel, yet still no concrete problem can be located. For technicians, the experience is nothing to celebrate either. Let’s face it, we all have better things to do besides taking the truck into the shop or spending time trying to re-create a problem. Let’s take a look at four basic steps that can help to more accurately and efficiently diagnose and resolve fault code issues.

Most of us have been on the customer side reading those fateful words for something where we know a problem exists. The frustration increases to monumental proportions when the problem is a blaring fault code indicator light on the instrument panel, yet still no concrete problem can be located. For technicians, the experience is nothing to celebrate either. Let’s face it, we all have better things to do besides taking the truck into the shop or spending time trying to re-create a problem. Let’s take a look at four basic steps that can help to more accurately and efficiently diagnose and resolve fault code issues.