Mitchell 1 was honored to support the Service Information Skills station at the Arkansas Technician Championship, held Friday, June 26, at the Embassy Suites Convention Center in Rogers, Arkansas. It’s always a highlight for our team to take part in these competitions and see firsthand the incredible talent and dedication of the technicians who keep our industry moving.

Trouble Logging In? Reset Your Password in Minutes

Do you have about a million passwords floating around in your head? If you’ve forgotten your password — or need to reset your password — to access ProDemand or TruckSeries repair information software, it’s quick and easy! Just follow these steps…

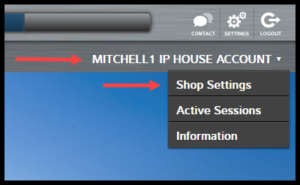

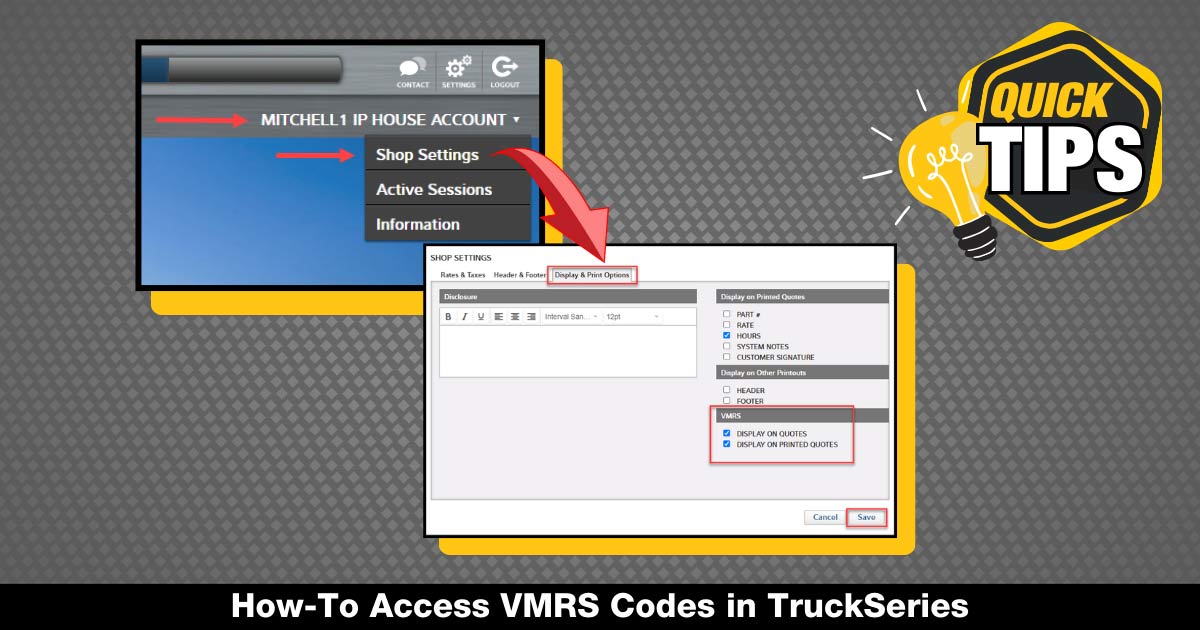

Quick Tip: How-To Access VMRS Codes for TruckSeries Users

Here’s a Quick Tip to access Vehicle Maintenance Reporting Standards (VMRS) codes for our TruckSeries users. Learn where to find…

Here’s a Quick Tip to access Vehicle Maintenance Reporting Standards (VMRS) codes for our TruckSeries users. Learn where to find…

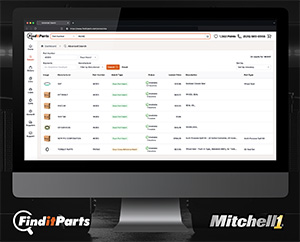

Parts Sourcing for Heavy-Duty Trucks Just Got Easier with FinditParts

Finding the right parts for heavy-duty trucks just got easier. Mitchell 1 and FinditParts, Inc. have teamed up to integrate the FinditParts Infinite Warehouse catalog with Manager SE Truck Edition, streamlining Class 4-8 vehicle repairs with the first online parts catalog of its kind.

Finding the right parts for heavy-duty trucks just got easier. Mitchell 1 and FinditParts, Inc. have teamed up to integrate the FinditParts Infinite Warehouse catalog with Manager SE Truck Edition, streamlining Class 4-8 vehicle repairs with the first online parts catalog of its kind.

What’s Up With All the Different Fault Code Numbers?

Heavy-duty truck fault code name structures can be particularly confusing when looking up service information for the uninitiated. Experienced truck techs know their way around OBD II codes, but If you are new to these SAE J1587 or J1939 and OE codes, this blog will make it easier for you to look up these codes.

Heavy-duty truck fault code name structures can be particularly confusing when looking up service information for the uninitiated. Experienced truck techs know their way around OBD II codes, but If you are new to these SAE J1587 or J1939 and OE codes, this blog will make it easier for you to look up these codes.

How Tool Organization Fuels Efficient Truck Fleet Repair

In fleet repair, organized tools are as vital as a library’s cataloging system. Missing tools, like misplaced books, waste time and hinder productivity. An inventory system ensures efficiency, professionalism, and prevents losses—especially the elusive screwdriver!

In fleet repair, organized tools are as vital as a library’s cataloging system. Missing tools, like misplaced books, waste time and hinder productivity. An inventory system ensures efficiency, professionalism, and prevents losses—especially the elusive screwdriver!

Three Steps to Avoid Disasters When Lifting Vehicles

Learn from a master technician’s negative experience lifting vehicles or heavy components during service. This warning story is meant to help mitigate disasters by encouraging planning with the key ingredients: information, lifting equipment and patience. Following these safety steps can literally make a life-saving difference in your shop.

Learn from a master technician’s negative experience lifting vehicles or heavy components during service. This warning story is meant to help mitigate disasters by encouraging planning with the key ingredients: information, lifting equipment and patience. Following these safety steps can literally make a life-saving difference in your shop.

Teardown Time: Haste Can Make Waste for Transmission Disassembly

As tempting as it may be, taking this fast and dirty approach to transmission disassembly can, unfortunately, increase the likelihood you could miss the problems that led to the need for a transmission overhaul in the first place. Ensure minimal road downtime with quick yet accurate repair jobs using TruckSeries Repair Information.

As tempting as it may be, taking this fast and dirty approach to transmission disassembly can, unfortunately, increase the likelihood you could miss the problems that led to the need for a transmission overhaul in the first place. Ensure minimal road downtime with quick yet accurate repair jobs using TruckSeries Repair Information.

If It Waddles, It May Not Be a Duck

Operators often feel the “waddle” or side-to-side movement that trucks experience at low speeds. But, as the vehicle’s speed increases, this swaying sensation then transitions to a more intense roughness or vibration. Here’s how to address the commercial truck diagnosis of a rig that starts driving like a duck.

Operators often feel the “waddle” or side-to-side movement that trucks experience at low speeds. But, as the vehicle’s speed increases, this swaying sensation then transitions to a more intense roughness or vibration. Here’s how to address the commercial truck diagnosis of a rig that starts driving like a duck.

7 Most Common Truck Repairs and and the Probable Causes

Medium and especially heavy-duty trucks experience much more wear and tear than our average automobiles, so damage is inevitable. Whatever the cause, it’s always a best practice to hone your diagnostics and repair knowledge for the most frequent truck issues.

Medium and especially heavy-duty trucks experience much more wear and tear than our average automobiles, so damage is inevitable. Whatever the cause, it’s always a best practice to hone your diagnostics and repair knowledge for the most frequent truck issues.