The heavy truck engine compartment is a busy environment to say the least. Much like popular cities such as San Francisco and New York, space always comes at a premium.

In order to optimize all the available space in the engine compartment, OEMs have turned to integrating ancillary items with the goal of more effective use of space. In doing so, they provide other benefits as well.

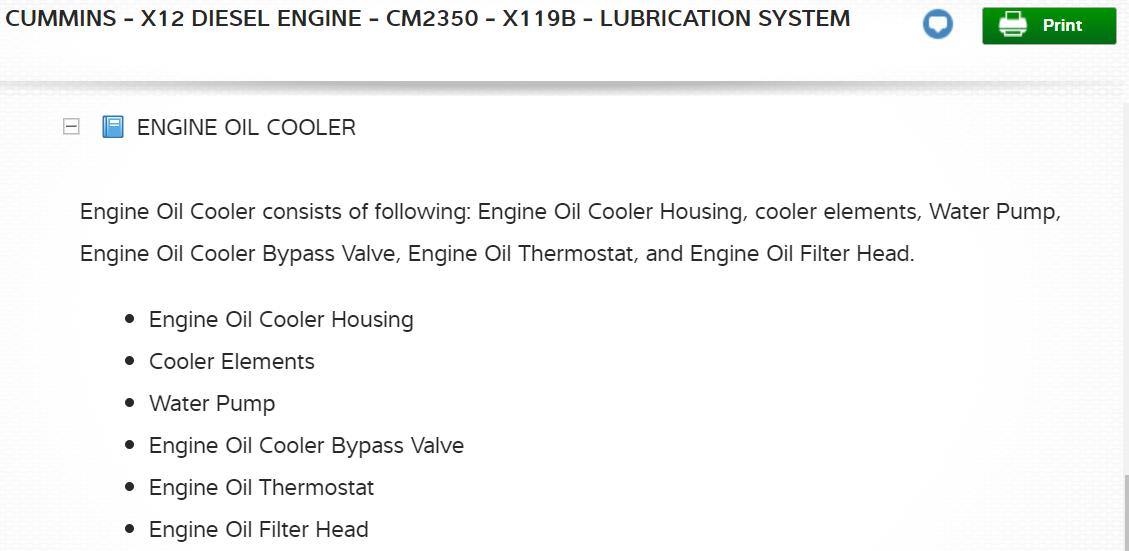

For example, many lubrication and cooling systems on vehicles today have seen much component integration for space maximization. Lubrication systems using engine coolant to control temperature means the two systems have a point of integration.

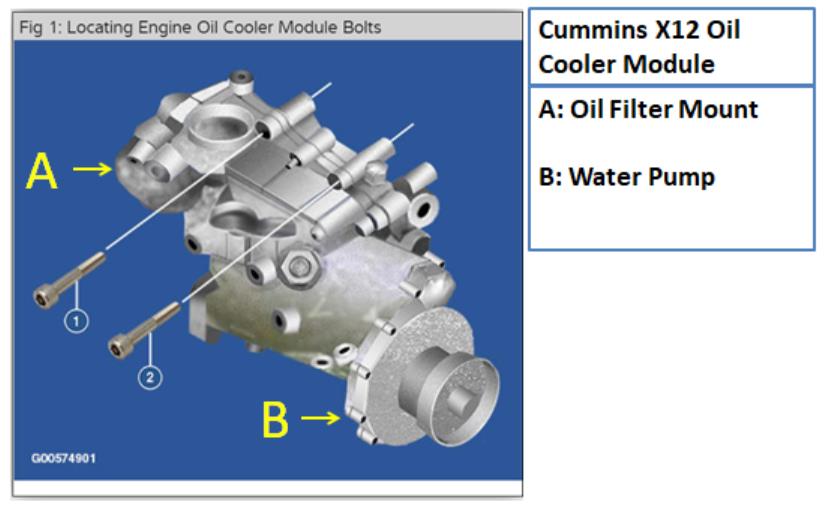

Previously the coolers, thermostats, pumps and filters had individual positions within the casting of the main engine block. Now they are added to a module that creates its own provision for all, without increasing the complexity of the engine block casing. This module not only provides mounting for components but also integral passages for fluids that eliminate the need for extra hoses and lines. This simplifies the engine bay and reduces the amount of components that are subject to failure or routine maintenance, aiding reliability and lowering operation costs.

Combine that all with the help that Mitchell 1’s TruckSeries truck repair software can offer you and your shop, you have a winning partnership!

Note: Cooler elements are located within the module housing.

Want to learn about TruckSeries?

Request a FREE DEMO today!

You may also like to read:

Tips for Hydraulic Brake Maintenance