Could Not Duplicate. No Problem Found

Most of us have been on the customer side reading those fateful words for something where we know a problem exists. The frustration increases to monumental proportions when the problem is a blaring fault code indicator light on the instrument panel, yet still no concrete problem can be located. For technicians, the experience is nothing to celebrate either. Let’s face it, we all have better things to do besides taking the truck into the shop or spending time trying to re-create a problem. Let’s take a look at four basic steps that can help to more accurately and efficiently diagnose and resolve fault code issues.

Most of us have been on the customer side reading those fateful words for something where we know a problem exists. The frustration increases to monumental proportions when the problem is a blaring fault code indicator light on the instrument panel, yet still no concrete problem can be located. For technicians, the experience is nothing to celebrate either. Let’s face it, we all have better things to do besides taking the truck into the shop or spending time trying to re-create a problem. Let’s take a look at four basic steps that can help to more accurately and efficiently diagnose and resolve fault code issues.

When all systems are operating properly, today’s newer diesel engines do not produce smoke like older diesel engines used to. The days of “rolling coal” are over, and this is a great thing for our health and the environment, too. Learn about modern day smoke tests from our knowledgeable truck pros in this latest edition of our TruckSeries blog.

When all systems are operating properly, today’s newer diesel engines do not produce smoke like older diesel engines used to. The days of “rolling coal” are over, and this is a great thing for our health and the environment, too. Learn about modern day smoke tests from our knowledgeable truck pros in this latest edition of our TruckSeries blog. Ever try to find the light switch in the middle of the night in an unfamiliar room? Well, walking around in the dark half asleep is much like trying to diagnose a diagnostic trouble code or a drivability issue without a scan tool on today’s trucks. But maintaining that scan tool is just as important as using it. Learn from our own Jake Schell, on how important these scan tools truly can be.

Ever try to find the light switch in the middle of the night in an unfamiliar room? Well, walking around in the dark half asleep is much like trying to diagnose a diagnostic trouble code or a drivability issue without a scan tool on today’s trucks. But maintaining that scan tool is just as important as using it. Learn from our own Jake Schell, on how important these scan tools truly can be. Time is money when you are working flat rate but maybe some of these accidents could have been prevented by taking the little extra time it takes to research the jack and lifting information. Take advantage of all the information provided in Truck Series to lift that truck safely and prevent a possible accident.

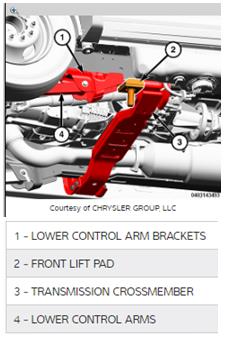

Time is money when you are working flat rate but maybe some of these accidents could have been prevented by taking the little extra time it takes to research the jack and lifting information. Take advantage of all the information provided in Truck Series to lift that truck safely and prevent a possible accident. While road hazards may not be avoidable and are well beyond the control of the technician in the shop, tire maintenance is a step technicians may take to keep tires in good order. Learn how Mitchell1 TruckSeries can help you out here.

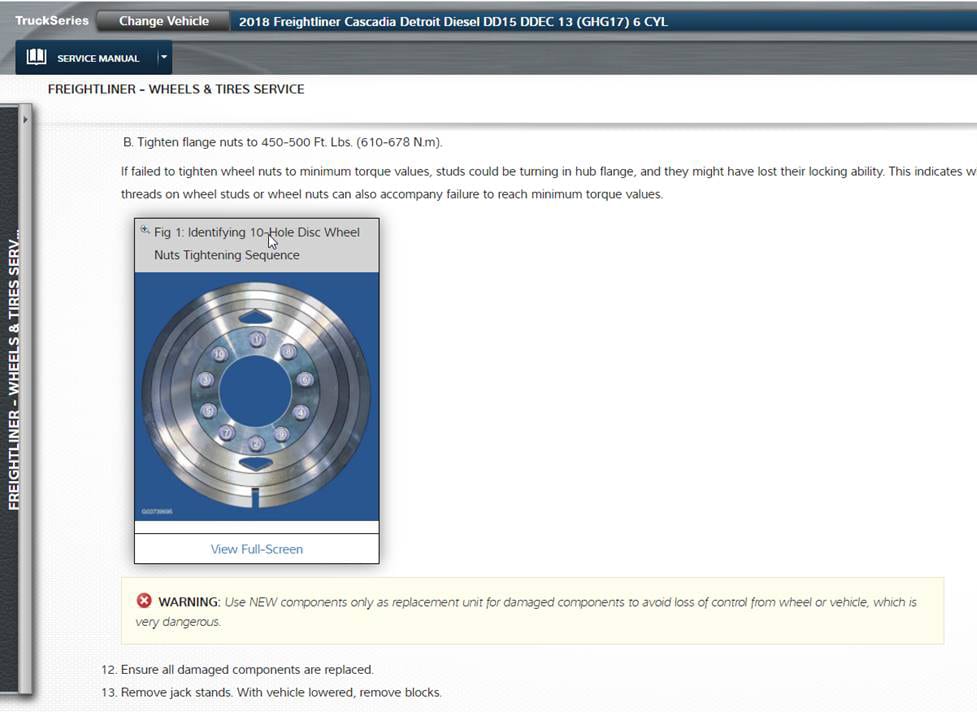

While road hazards may not be avoidable and are well beyond the control of the technician in the shop, tire maintenance is a step technicians may take to keep tires in good order. Learn how Mitchell1 TruckSeries can help you out here. There is no question that being familiar with a fault code — both the cause and correction — can be a great time-saver for the technician. After all, some diagnostic procedures can take a lot of time and effort as the technician works through the diagnostic steps to systematically eliminate potential issues. By knowing where the fault generally occurs, the technician can go directly there without going through all the steps that lead to that problem point. But, this can be risky. Learn how Mitchell 1 TruckSeries can help you out!

There is no question that being familiar with a fault code — both the cause and correction — can be a great time-saver for the technician. After all, some diagnostic procedures can take a lot of time and effort as the technician works through the diagnostic steps to systematically eliminate potential issues. By knowing where the fault generally occurs, the technician can go directly there without going through all the steps that lead to that problem point. But, this can be risky. Learn how Mitchell 1 TruckSeries can help you out! Virtually every technician in the vehicle service industry with more than a few years of experience knows the mechanic proverbs passed from one generation to the next. These proverbs are basic wisdom in a simple, yet memorable form that helps the technician in performing maintenance and repairs.

Virtually every technician in the vehicle service industry with more than a few years of experience knows the mechanic proverbs passed from one generation to the next. These proverbs are basic wisdom in a simple, yet memorable form that helps the technician in performing maintenance and repairs.