The serpentine belt of today is certainly an improvement over the old style fan belts. As a technician I remember some of the older cars using upwards of six belts. You can imagine what a nightmare it was replacing all those belts. You could also bet there would be a few cuts and scrapes along the way while removing and installing those belts. Serpentine belts just about eliminated most of those headaches and sure made the installation much smoother and quicker.

To remove and install a new serpentine belt all that is required is knowing where the tensioner is located and a good breaker bar. Most vehicles nowadays usually have a belt routing sticker located somewhere in the engine compartment, making it even easier.

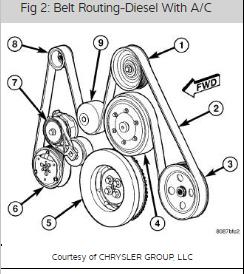

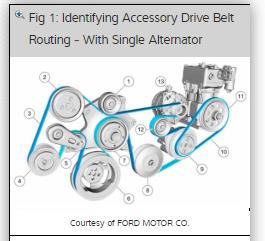

So imagine now you have the hood open, you removed the old belt, ran to the parts room for a new belt only to get back and find there isn’t a routing sticker. Luckily for you, Mitchell1 commercial truck repair information provides routing diagrams for most vehicles – see below.

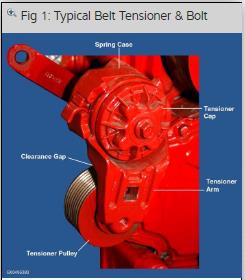

Belt routing diagrams are generally located in the “Engine Mechanical” or “Cooling System” articles. Included in many of these sections are component identification, pulley alignment, tension chart, belt and tensioner inspection procedures, along with any adjustments if applicable. They may also include any tensioner bolt torque specifications if so required.

So put your mind at ease and don’t worry! Mitchell 1’s truck repair software has taken all the guess work out of the correct serpentine belt routing, removal and installation procedures to get that truck back on the road quickly. You just have to look at the belt routing graphic to see how important is is to have this type of information handy.