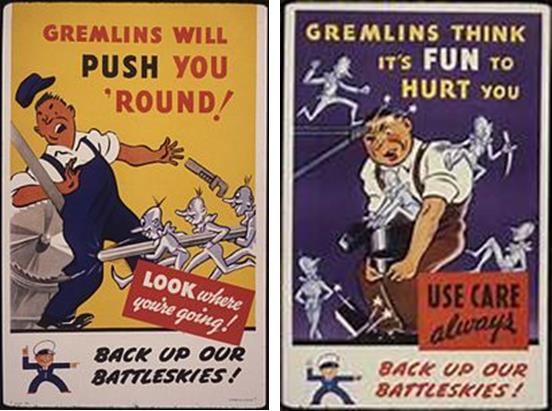

Electrical Gremlins

The term “gremlin” dates from World War II when it referred to mythical creatures that caused mechanical or electrical faults in airplanes or machinery. Their modern equivalent lives on in car and truck electrical systems. Electrical faults can be some of the most frustrating problems for a technician to diagnose and repair.

Research has shown that the most common causes of electrical problems in modern trucks are corrosion, poor harness connections, and chaffed wiring insulation.

Corrosion in wiring harness connectors and inside wiring insulation will result in an excess of resistance in the circuit. Higher current circuits such as headlights and blower motors are typically less prone to problems. However, low current circuits associated with electronic control modules are more sensitive. A small amount of corrosion can skew the sensor signal to an ECM, resulting in setting a fault code and reduced engine performance.

Corrosion may enter an electrical circuit through poorly sealed connectors or wiring insulation that chaffed through as a result of not being secured properly. Piercing wiring insulation with a test light or multi-meter probe can also open a path for moisture, which ends in a corroded wiring. Yet another source of circuit faults is wiring harness connector terminals that have lost some of their tension, resulting in open circuits or voltage drops.

Corrosion (and those pesky gremlins) is something all techs encounter at one time or another, so it’s especially important to stay on top of electrical maintenance issues. TruckSeries can help you there – with tons of maintenance information for all makes and models of Class 4-8 trucks.

And here’s more good information on the subject from Heavy Duty Trucking magazine:

- April, 2015 issue: How Corrosion Causes Electrical Problems

- March 2015: Spec’ing Electrical Parts for a 12-Year Life