Are you ready to repair ADAS?

We’ve all heard the old adage, “no news is good news.” While that saying may sound encouraging, the logical part of our mind probably wonders what’s going on with the “no news” part.

When it comes to vehicle operations, there are a number of sensors monitoring conditions throughout the vehicle to let the driver know the current status. Generally, we expect this vehicle condition feedback to be telling the truth, or at least bringing a potential problem to our attention, even if it ends up being false.

In truth, many technicians don’t even bother looking at the electronics of those feedback systems unless a problem is noted. However, when it comes to Advanced Driver Assistance Systems (ADAS), and especially collision avoidance, it is critical to make sure the system is in good shape at all times to avoid an accident.

ADAS features are not meant to replace conscientious vehicle operation. Instead ADAS provides the driver with an additional input to help make operation safer. There are many “human factors” that can impact these advances in driver assistance, like when the operator becomes overly dependent on these warning systems once familiarity begins to take hold.

For instance, nearly everyone who needs to wake up on time depends on an alarm clock, but of those who do, how many are able to say the alarm has never been the cause of waking up late? Granted, ignoring the alarm and going back to sleep isn’t an alarm failure.

Similarly, if the driver has become accustomed to an ADAS feature warning that triggers a false alert when danger is not present and ignores the warning, then the potential for an accident goes up. The same is true if the ADAS feature does not sound an alert or fails to display when an object is in a danger spot — there is potential for a collision.

It is unlikely that the shop can control driver attention during vehicle operation, so what may be done from a maintenance perspective to help mitigate this problem?

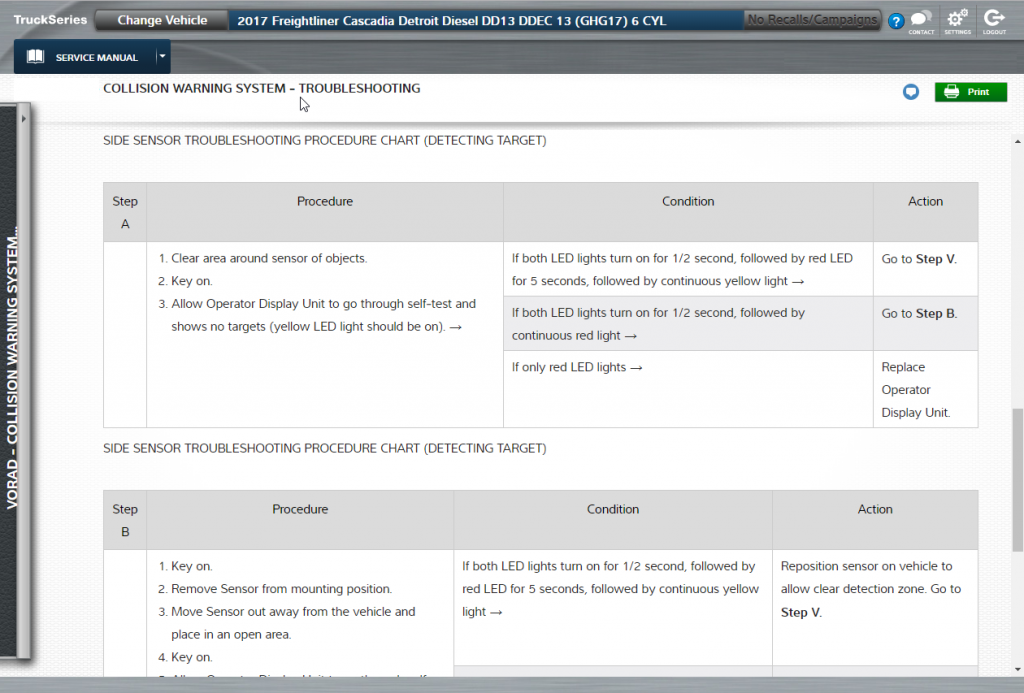

First, make an operational inspection of the ADAS systems part of the regular maintenance schedule. The service information for these systems provides procedures and specifications for proper operation. Just because an alarm sounds in the vehicle does not guarantee the warning is correct. After all, even a stopped clock is right twice a day.

Second, recognize that as vehicles become increasingly more complex, service and inspection points will need to be reviewed and modified accordingly. From a technician perspective, the days of “if it isn’t broke don’t fix it,” or “out of sight, out of mind” have been replaced by a need to confirm systems are sound and operating properly.

There is little question that ADAS features can help avoid accidents. However, to make sure the full effectiveness of ADAS is employed, fleets need to ensure drivers understand proper operation of the system and that the shop maintains the system to its full potential. Let’s keep everyone moving down the road as safely as possible.

Want to learn about TruckSeries?

Request a FREE DEMO today!

Also Read: