Keeping tires inflated to the proper pressure helps to improve tire life, fuel mileage and vehicle safety. Obviously, on a tractor and trailer there are a good number of tires to check and maintain. It takes time to check and balance the air pressure on 18 or more wheels. Thus, a tire inflation system can truly help the operator and maintenance personnel maintain uniform tire pressures with considerably less effort.

Still, the convenience of a tire inflation system does not mean tires may be ignored.

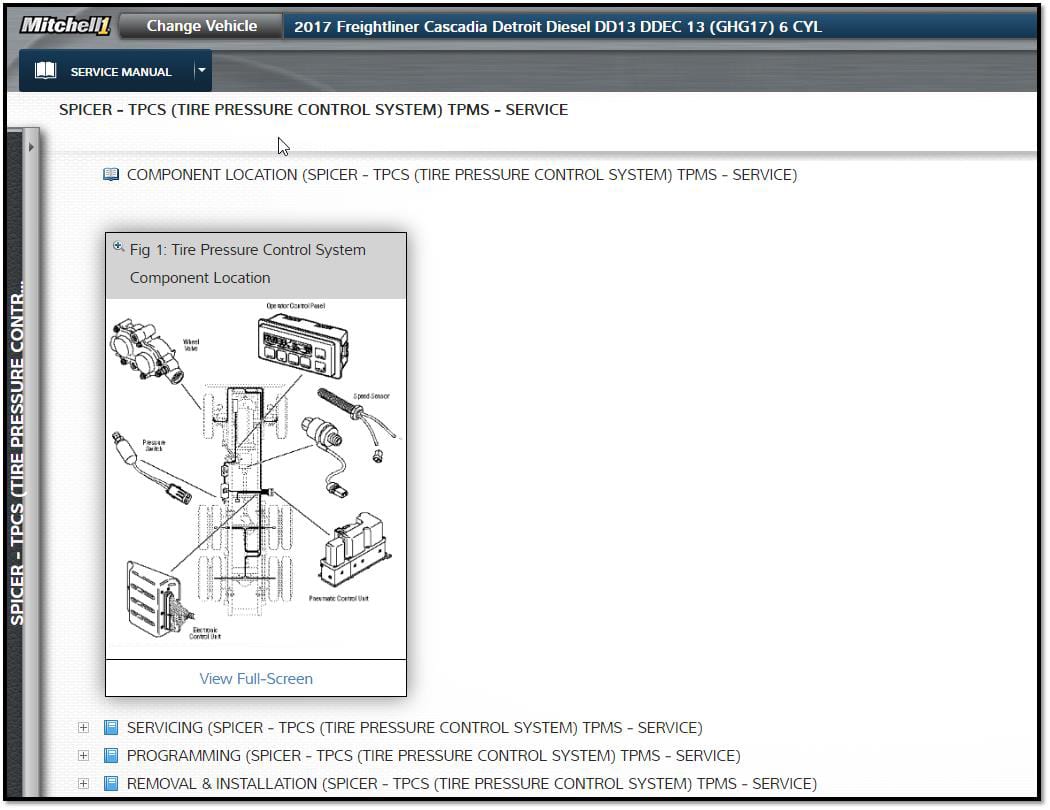

Even though trailer tire inflation systems have been around for a number of years, tire inflation systems for trucks and tractors are still relatively new. These systems add a layer of complexity to maintenance and repair well beyond regular tire maintenance. With the inclusion of a control module, operator controls and assorted valves and piping, the tire inflation system demands some technical know-how to repair and maintain.

As with most vehicle systems, while there are similarities in the components and operation between manufacturers, there are also distinct differences. So, before attempting to service any tire inflation system, be sure to consult the proper service information to become familiar with the operation and system layout. Take care, because in some instances your routine steps can create issues with the tire inflation system.

For instance, it is likely second nature to ensure the Schrader valves are securely installed in the valve stems. However, on some tire inflation systems having the Schrader valve in place will result in a mis-inflated tire and set a trouble code. In such systems, the Schrader valve is removed and a control valve attached to the valve stem.

When the Schrader valve is left in place, the system inflates the tire as needed. However, a part of the system includes reducing air pressure in the tire as needed. When the Schrader valve remains in place the air cannot escape past the valve. As the system monitors the pressure and is unable to detect a deflate action when requested, a code is set.

The air filter is another aspect of tire service that if overlooked could impact inflation performance and set a code. The control valve at the wheel may include a filter for the air passing to and from the tire during automatic inflation adjustments. This filter is typically to be replaced at each tire replacement service. If the filter becomes restricted, the inflation balance can be affected resulting in mis-matched pressures and a subsequent trouble code.

During regular service, ensure the air supply is directed from a clean and dry source. In addition, make sure the piping to the tires and associated system components are securely fastened and in proper working order.

The tire inflation systems make for a great way to maintain tires for optimum performance and life. Although there is additional complexity with the overall vehicle, the ease of use for the operator and a uniform tire pressure helps to keep the truck moving smoothly down the road.

Want to learn about TruckSeries?

Request a FREE DEMO today!

Also Read: