All About P-Codes for Trucks

Though they were required by 1996 in light-duty vehicles, P-codes are a relatively new development in the commercial vehicle industry. Technicians are coming across them more and more, especially in medium-duty vehicles. So what exactly are they, why is the industry moving in that direction, and how can you look them up in Mitchell 1 products? Well, read below for the answers!

P-Codes or On-Board Diagnostic-II (OBD-II) codes are part of the SAE standards for fault codes that were developed for J2012 standards in passenger vehicles, light-duty and medium-duty trucks. We are now even seeing them in a few heavy-duty trucks. These codes can be read with an OBD-II scanner that has a 16-pin connector that will connect to all OBD-II systems. The codes themselves also have a standard format that is the same across all makes. These codes are beneficial for techs doing emissions & performance diagnostic work.

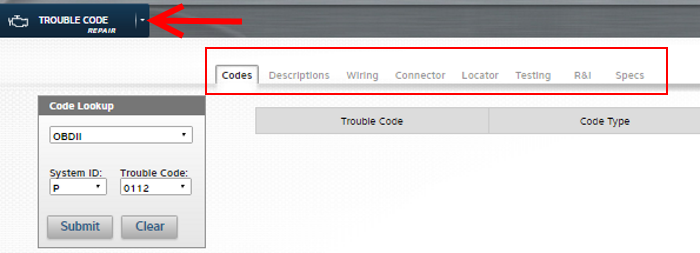

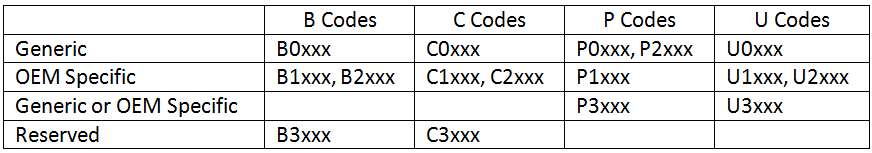

The first character in a code is a letter indicating the vehicle system related to the code. The “P” at the beginning of a P Code designates that this is a powertrain code. There are different types of codes depending on the system in the vehicle. Here is a table to show the different types:

All OBD-II codes begin with one of these letters and then are followed by 4 more digits (example P0113). The 2nd digit in an OBD-II code will designate if the code is generic or OEM specific; see below:

The 3rd digit generally designates what sub-system the fault is in. For example, P0112 translates to Intake Air Temperature Sensor 1 Circuit Low (Bank 1). The 3rd digit is a 1, and for general codes, this will designate that this is a Fuel & Air Metering code. Here are the generic, P-Code, system numerical codes for the 3rd digit along with some OEM Specific ones that are defined.

The 4th & 5th digits designate what type of fault is present, and can have so many meanings we won’t address those here. You can find information on codes in Mitchell 1’s TruckSeries Repair module, under Engine Performance > Testing & Diagnostics.

See below for examples of the code information you can find in TruckSeries (Figure 1):

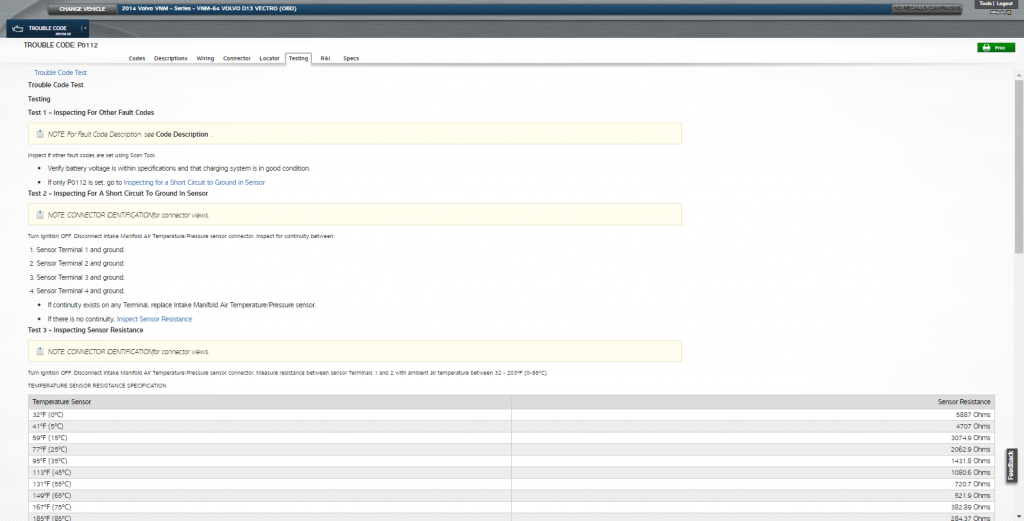

Trouble Code Repair in TruckSeries

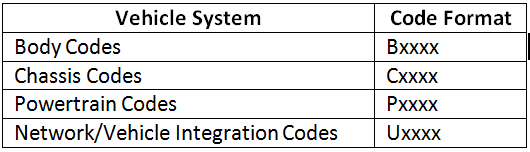

The Trouble Code Repair module in TruckSeries (also known as RepairConnect) gives detailed diagnostic information when specifically working on P-Codes or U-Codes. This module is great when looking up specific codes for your vehicle. It has multiple tabs, where you can look at different information for the selected code. The Descriptions tab — as you would expect — has the code descriptions & the monitor descriptions. The Wiring tab has both the system’s wiring diagrams, and circuit diagrams for the specific code selected. The Connector tab has the connector views that you need to diagnose a circuit. The Locator tab has component location graphics for all the components a code may cover. The Testing tab has the procedures to follow to diagnose a code. The R&I tab has component removal and installation procedures for any component you may need to replace. The Specs Tab has all the electrical and torque specifications you will need for the code.

Looking up an OBD-II P-Code in the Trouble Code Repair module – see Figure 2 below.

Example of circuit diagram, selected from Wiring Tab – see Figure 3 below.

Example of testing information for OBD-II Codes in Trouble Code Repair module – see Figure 4 below.

The OBD-II codes system is a great way to standardize fault codes, and you’ll be seeing more and more of the codes in the commercial vehicle industry. Check out the tools in TruckSeries that can help you use these codes to diagnose vehicles more efficiently.

Read More

- Learn more about Truck Series

- Learn about trouble code procedures in the RepairConnect module of TruckSeries

- From AVI: Anatomy of the DTC