Helping Your Truck Stay Right Side Up!

In the trucking industry today there are so many things that contribute to accidents. New drivers with limited experience, larger multi-trailer vehicles, increased load variability, additional demands on drivers, increased traffic density, numerous in-the-cab distractions, and more. Today more than ever, fleets need every opportunity to rev up safety while still meeting the demands of their jobs and the needs of their customers.

New ABS and stability technologies can help. These systems offer a proven way to help reduce the occurrence of loss-of-control events, and some even help with rollovers.

New ABS and stability technologies can help. These systems offer a proven way to help reduce the occurrence of loss-of-control events, and some even help with rollovers.

For passenger cars, researchers at the Insurance Institute for Highway Safety found that Electronic Stability Control (ESC) systems reduce the risk of fatal multiple-vehicle crashes by 32 percent.

The new research confirms that ESC reduces the risk of all single-vehicle crashes by more than 40 percent — fatal ones by 56 percent. The researchers estimate that if all vehicles were equipped with ESC, as many as 10,000 fatal crashes could be avoided each year. For heavy duty trucks, The University of Michigan Transportation Research Institute (UMTRI) estimates that ESC systems on tractor-trailer trucks prevent 4,659 crashes, 5,909 injuries, and 126 heavy truck crash deaths each year.

Fleet owners are not the only ones that like these systems. In June of 2015, The National Highway Traffic Safety Administration unveiled a new rule requiring truck tractors and new large buses to have electronic stability control technology by 2019

But what is the difference between traction control and stability control?

Well, first of all we should talk about anti-lock braking systems (ABS) — from which both traction control and stability control are born. Then we will go through the other iterations of this system.

ABS

ABS uses wheel speed sensors to determine if one or more wheels are trying to lock up during braking. If a wheel tries to lock up, a series of valves limit or reduce the braking on that wheel. This prevents skidding and allows you to maintain steering control.

Traction control

Traction control uses brakes to control spinning wheels to force power to another wheel. Individual sensors detect when wheels are spinning faster than their counterparts and apply brakes — very quickly — to reroute power to a wheel that may have more traction. As an example with off-road vehicles, traction control is immensely helpful when one tire is suspended in midair.

Stability control

Stability control is an evolution of traction control that will apply the brakes or even cuts the power to any number of wheels to send a vehicle in an intended direction. Imagine driving on a snowy road with the steering wheel cranked to one side, but the vehicle is plowing straight ahead. Stability control often cuts power and brakes wheels to move the vehicle where a driver is pointing it.

Roll stability

Roll stability counteracts the inclination of a vehicle to tip over while changing direction. This tendency typically occurs while turning. If the lateral force is great enough, one side of the vehicle may begin to lift off the ground, creating the potential for the vehicle to roll over. Several factors influence a vehicle’s sensitivity to lateral forces, including the load’s CG height, load offset, road adhesion, suspension stiffness, frame stiffness, and track width of the vehicle.

Taking care of these systems

The first line of defense with any of these systems is regular factory recommended maintenance. Keeping these systems in tip top shape will help keep drivers safe and costs down. If something happens to go wrong, diagnostics on these systems can be complicated. But having access to online truck repair software can help.

For instance, TruckSeries from Mitchell 1 has diagnostic and repair information for all major brands of stability, traction and roll stability systems. Figure 1 shows an example of our truck repair information showing description information about a roll stability system.

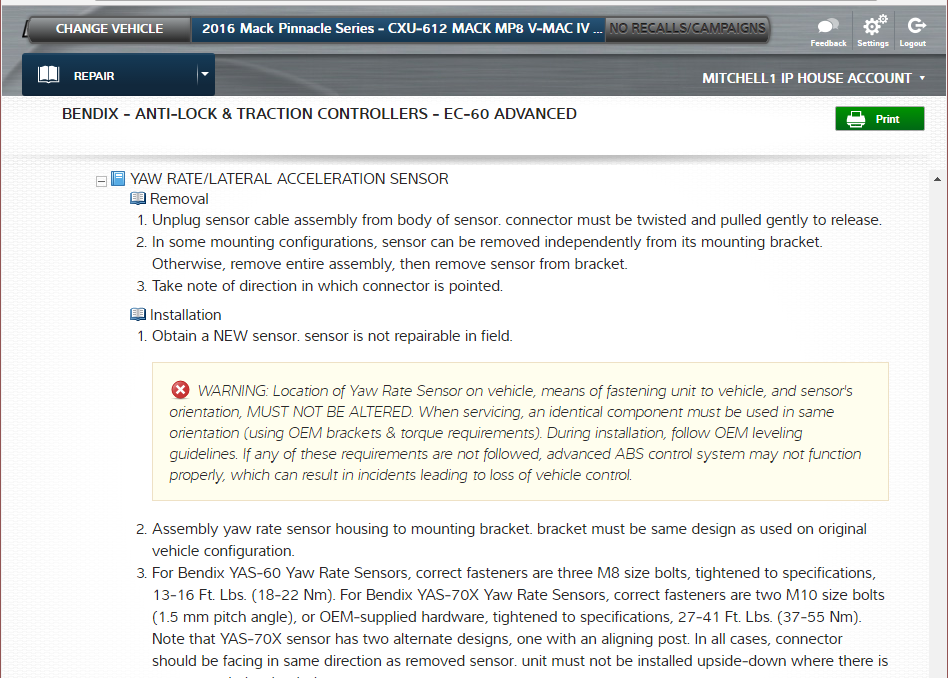

And Figure 2 below shows an example of the R&I procedure for the yaw rate/acceleration sensor.

This is just a very small sample of the vast amount of repair information we have available to our customers. No matter what system you have, TruckSeries can help you get the job done right.

- Learn more about TruckSeries

Also read: