Press Releases

Mitchell 1 ‘Thanks’ Automotive Service Professionals

July 7, 2025

Mitchell 1 has wrapped up its “Thank You Thursdays!” sweepstakes in recognition of Automotive Service Professionals Month (ASPM) throughout June. Each Thursday for six weeks, a lucky winner received a $100 gift card, announced on the Mitchell 1 Facebook page.

Read More

Read More

Michell 1 Names Guy Tiberio III the 2025 Educator of the Year

June 30, 2025

Congratulations to Guy Tiberio, the 2025 Mitchell 1 Educator of the Year! As an associate professor of automotive technology at Waubonsee Community College in Sugar Grove, Illinois, Guy has shaped the lives of many students in the industry.

Read More

Read More

Mitchell 1 Names Julian Moreno as the 2025 Automotive Technology Outstanding Student

June 17, 2025

Congratulating Julian Moreno from Omaha, Nebraska, for being named the 2025 Mitchell 1 Automotive Technology Outstanding Student! With his hard work and dedication, Julian earned a $2,500 scholarship and an all-expenses-paid trip to the NACAT conference in Detroit! Currently studying automotive collision repair at Metropolitan Community College, he aspires to own his own auto body shop one day.

Read More

Read More

Mitchell 1 Enhances ‘Job View’ in Manager SE with Expanded Features for Managing Revisions

May 27, 2025

Mitchell 1 introduces major enhancements to its Job View feature in Manager SE 9.2, giving service advisors greater flexibility by removing the nine-revision limit. Shops can now create unlimited revisions per vehicle, with each organized in its own tab — streamlining quoting, prioritization and customer approvals for faster decisions and improved overall workflow.

Read More

Read More

Mitchell 1’s Latest Sweepstakes ‘Thanks’ Automotive Service Professionals

May 15, 2025

In celebration of Automotive Service Professionals Month this coming June, Mitchell 1 is hosting the “Thank You Thursdays!” sweepstakes, offering a $100 gift card each week for six weeks. This initiative aims to honor automotive repair technicians for their vital role in ensuring vehicles operate safely and efficiently.

Read More

Read More

Mitchell 1 Hosts Sold-Out Shop Management Workshop in Philadelphia

May 6, 2025

Mitchell 1 hosted a successful spring shop management workshop in Philadelphia, attracting professional service advisors and shop owners. The event focused on enhancing shop efficiency using the Manager SE™ and ShopKey® systems, featuring new tools like the Job View and Expanded Revisions, along with marketing strategies through SocialCRM.

Read More

Read More

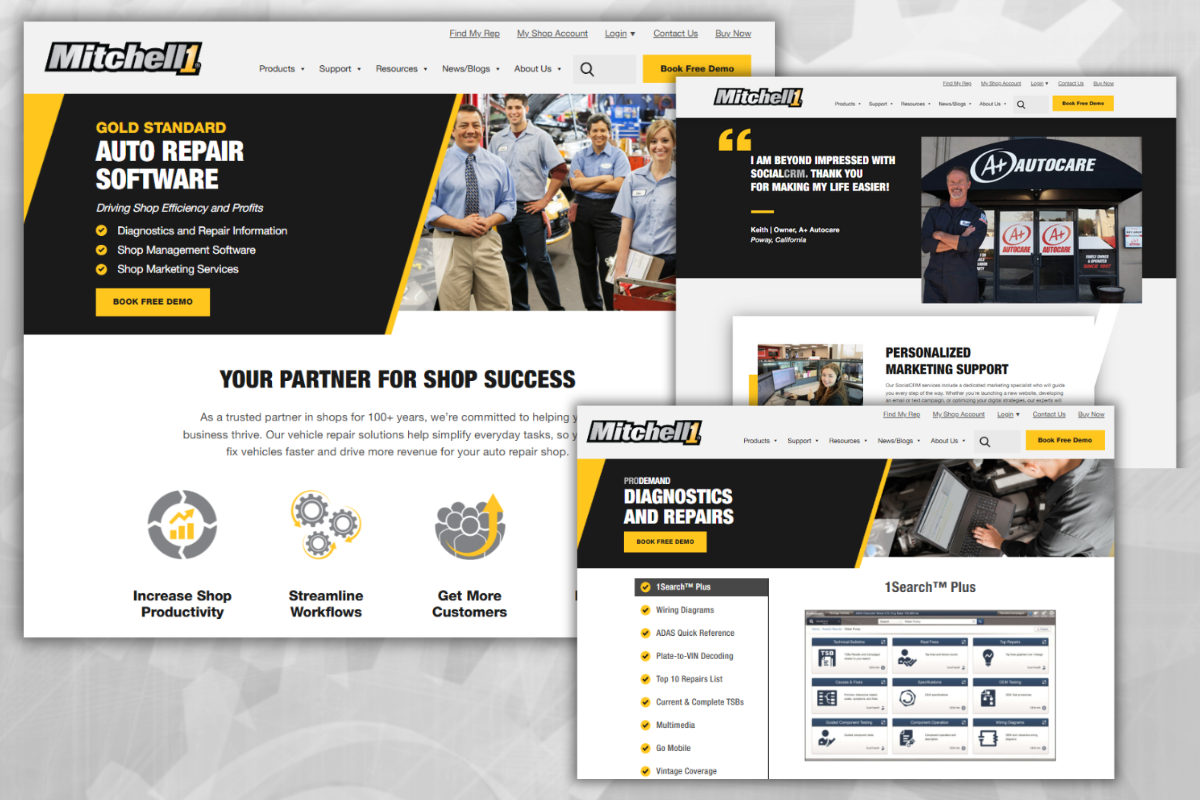

Mitchell 1 Launches Redesigned Website

April 8, 2025

Mitchell 1 has unveiled a redesigned website aimed at enhancing the experience for auto repair professionals. The user-friendly site features a streamlined navigation system that provides direct access to various sections, including detailed product information organized by repair, management, and marketing services. The resources page offers extensive support and training materials, while the news/blogs section includes improved search capabilities. With the theme “In your shop, at your side,” the new website showcases Mitchell 1’s century-long commitment to innovation and excellence, ensuring that customers can easily connect with support, purchase products, and book demonstrations.

Read More

Read More

Search

Keep in Touch

Be the first to learn about the freshest news, insights, and stories from our community.