Shop Connection Blog

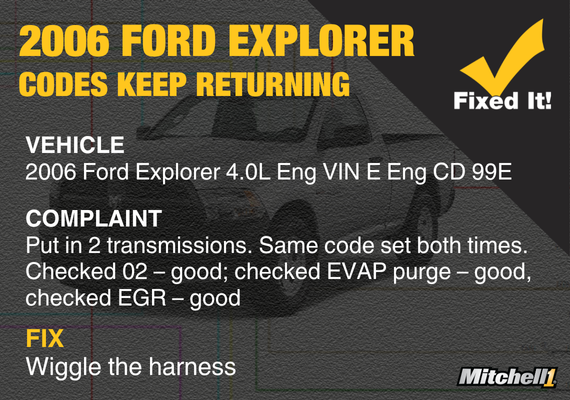

SureTrack Real Fix: 2006 Ford Explorer 4.0L Eng VIN E Eng CD 99E

June 20, 2025

A 2006 Ford Explorer repeatedly set codes P0161, P0403, P0443, P0645, and P0713—even after two transmission replacements and thorough sensor checks. The root cause was poor pin fitment or contamination near the EGR valve and PCM connector. Wiggling the harness while monitoring PIDs confirmed the intermittent connection issue.

Read More

Read More

Trouble Logging In? Reset Your Password in Minutes

May 23, 2025

Do you have about a million passwords floating around in your head? If you’ve forgotten your password -- or need to reset your password -- to access ProDemand or TruckSeries repair information software, it’s quick and easy! Just follow these steps...

Read More

Read More

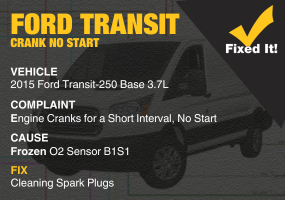

SureTrack Real Fix: 2015 Ford Transit – Crank No Start

May 12, 2025

2015 Ford Transit-250 with a 3.7L engine had a short crank issue despite starter replacement. No crank signal was detected. After verifying wiring and replacing the crank sensor, the issue persisted. Cleaning spark plugs and using wide-open throttle during cranking restored engine start and resolved the problem.

Read More

Read More

Why Wiring Diagrams Are Critical for Diagnosing Electrical Problems in Today’s High-Tech Vehicles

April 16, 2025

Modern vehicles are packed with complex electronics, making diagnostics tough. Mitchell 1’s Advanced Interactive Wiring Diagrams simplify the process with wire-to-wire navigation and searchable components—helping techs pinpoint issues faster, reduce errors, and minimize downtime. It’s the smarter way to troubleshoot today’s high-tech cars, including EVs and ADAS-equipped models.

Read More

Read More

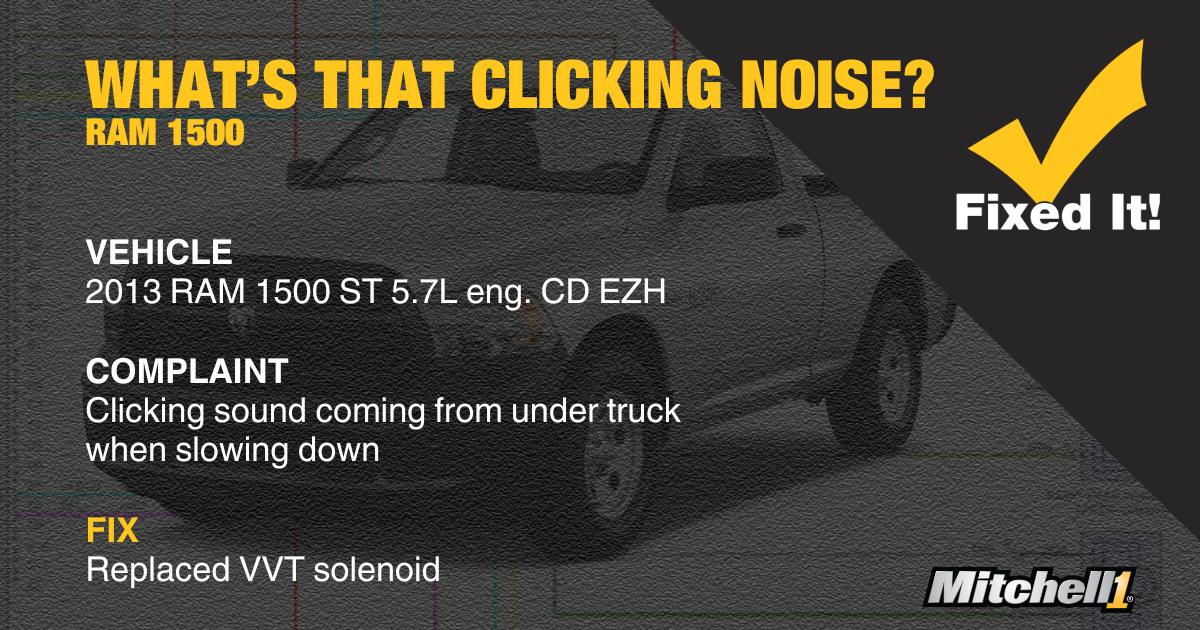

SureTrack Real Fix: 2013 RAM 1500 ST 5.7L eng. CD EZH

April 7, 2025

A 2013 RAM 1500 developed a clicking noise when coasting between 24–17 mph. The sound stopped in neutral. After inspecting driveline components and replacing front CV shafts, the issue persisted. Ultimately, replacing the VVT solenoid under the intake manifold eliminated the noise, confirming it as the root cause.

Read More

Read More

Boost Your Shop’s Reputation with Customer Review Management

March 27, 2025

Online customer reviews hold great power in shaping a customer’s perception of your shop... but the question is, are you leveraging those shop reviews to get the most out of them? Unleash the full power of reviews to drive in new customers and enhance loyalty for reputation boost!

Online customer reviews hold great power in shaping a customer’s perception of your shop... but the question is, are you leveraging those shop reviews to get the most out of them? Unleash the full power of reviews to drive in new customers and enhance loyalty for reputation boost!

Read More

Unlock a new level of customer engagement: Introducing our Enhanced Email Templates

March 24, 2025

Email marketing remains a vital tactic in today’s digital age. Mitchell 1 SocialCRM is enhancing its email templates to captivate customers and boost engagement. With customizable features and vibrant designs, these revamped templates will elevate your brand’s presence and keep your customers coming back for more!

Read More

Read More

Search

Keep in Touch

Be the first to learn about the freshest news, insights, and stories from our community.