Imagine the scene: The orchestra walks into the symphony hall, gets into position and does their final tuning before the performance begins. The noise, disconnected and without order is, to say the least, unpleasant. Then, the lights dim and the spotlights focus on the conductor who takes a bow, turns to the ensemble and begins to lead a gentle melody that makes one marvel at how the racket of the warm-up has now turned into this lovely sound.

Then suddenly the kettledrums erupt in a random flurry of drum beats that completely disrupt the rhythm of the music and make the startled audience wonder if this is some kind of discordant modern music. However, the maestro, having knowledge of the orchestra as well as the music being performed, knows instantly that something is amiss.

A truck service technician is like the conductor, tuned into the truck’s performance with special knowledge about the systems on the vehicle. In fact, today’s trucks are much like a finely-tuned orchestra; when all the parts are working in unison, they are a joy to behold. However, when one component goes awry, well, things are just not so enjoyable.

The engine and other powertrain components need to work in relation to one another to ensure the power makes its way to the wheels to move the truck. However, this relationship is often more akin to solo musicians playing on the same street than an orchestra.

For instance, the transmission could have experienced an issue without affecting in any way how the engine runs. Now, with today’s powertrain systems, there are multiple points where a transmission fault reflects in an engine performance issue and vice versa. To better obtain optimal performance, the systems interact more closely than ever before. Consequently, technicians must be aware of how these systems intermingle to be able to properly diagnose and repair them.

The vehicle systems could be working properly but a programmable setting is slightly off, resulting in no upshift to higher gear on a vehicle equipped with an automated transmission. This in turn results in lower fuel mileage.

Like never before, knowledge about how the various systems interact with one another assists the technician to make an accurate diagnosis and repair. Service information resources like TruckSeries from Mitchell 1 provide a general overview of how the systems work together. Becoming familiar with that information clearly helps the technician to be able to spot issues based upon how the systems interact.

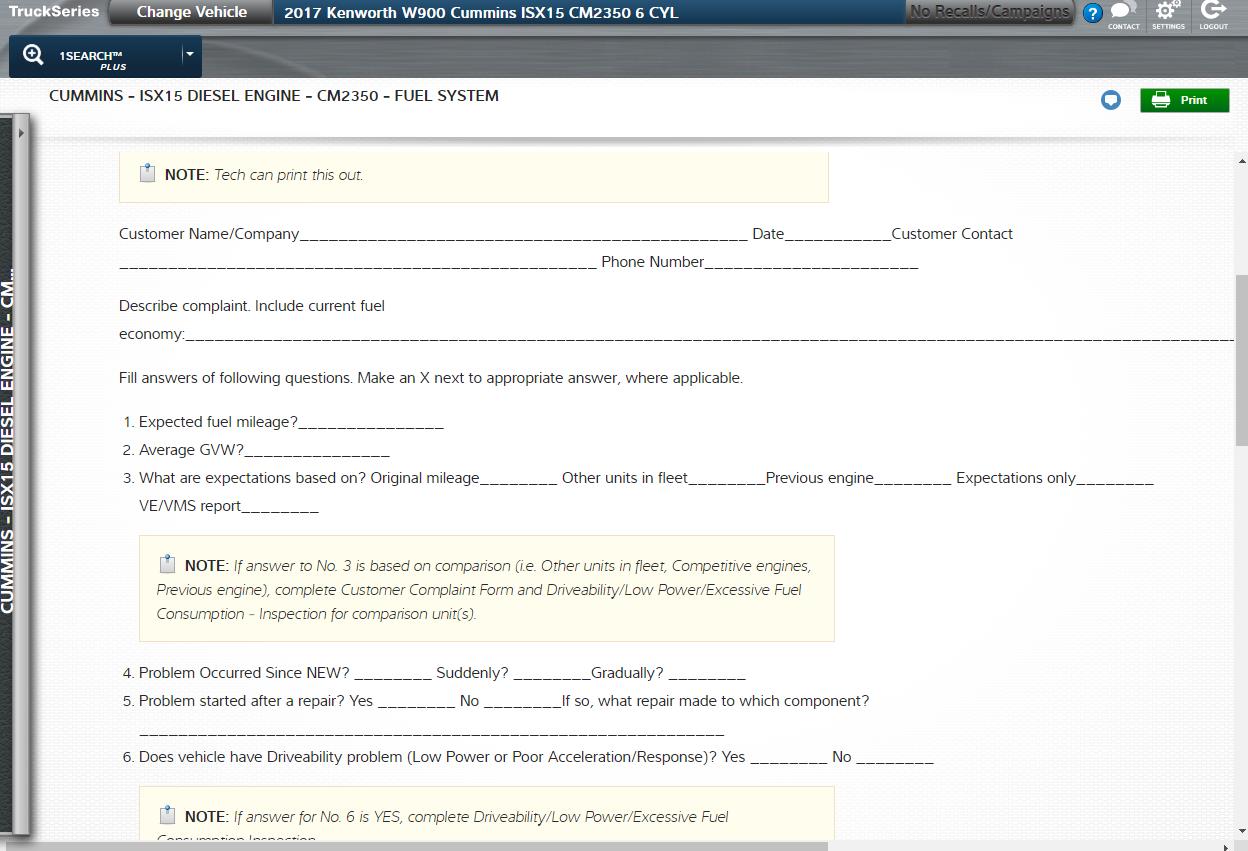

However, there is another critical element that goes beyond the service information, namely asking questions of the operator. It is not uncommon for the technician to not be able to duplicate a concern simply because the description of the problem did not really match what the operator was experiencing. Getting as much information as possible about the concern will increase the likelihood of isolating and repairing the issue.

Of course, knowing what to ask depends largely on knowing the system and its relationship to the other systems on the vehicle. In some cases, the service information will have questions to answer as well as points to note before the tech touches the vehicle. This step is as much a part of diagnosis as running through the test procedures.