Next time you have a Challenger in the shop, here’s a tip for performing a relative compression test to help determine if a cylinder has a mechanical issue that is causing a lack of compression.

Historically, to perform this test a compression gauge would have to be used, requiring the removal of the spark plugs and any components blocking the way to gain access.

But this new method of testing makes use of an oscilloscope and an amp clamp that supports 2000A.

Amperage draw is checked and graphed during cranking using an oscilloscope, the amount of peak amperage drawn for each cylinder during a compression stroke will increase or decrease in relation to the cylinder compression.

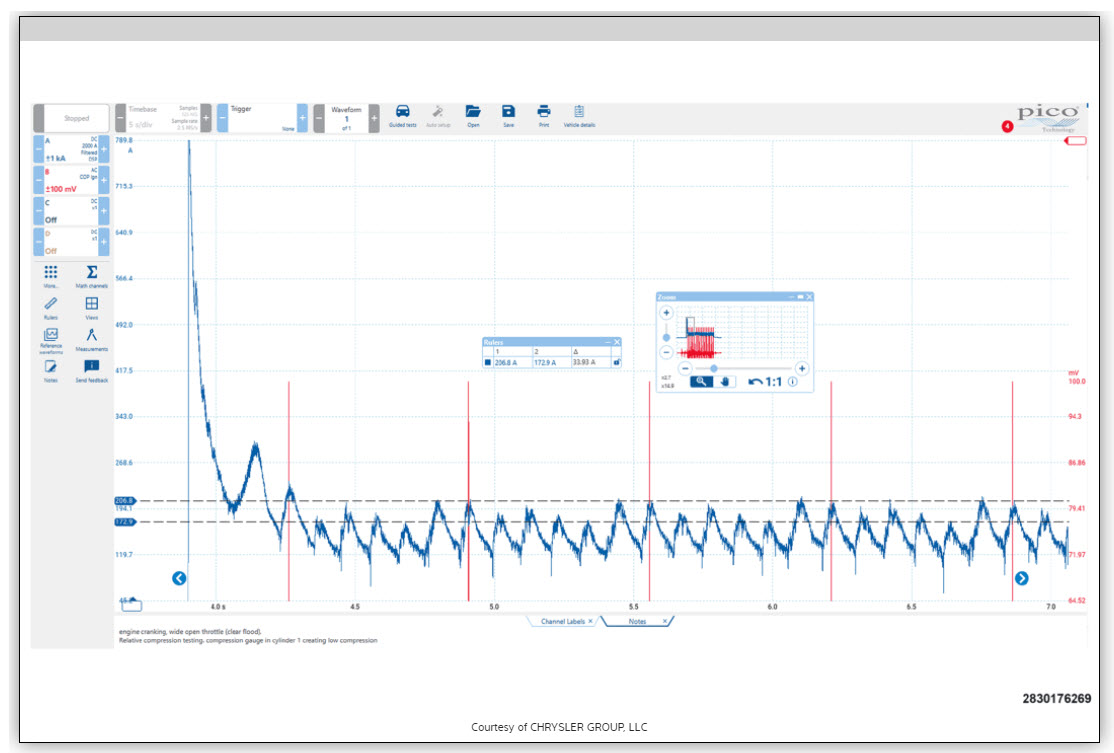

Cylinders with low compression will cause the starter motor to draw less amperage during the compression stroke which will be visible on the oscilloscope graph.

You must disable the fuel system to prevent the engine from firing. Sometimes this is as easy as cranking the engine with the accelerator pedal fully depressed. Otherwise you can typically remove a fuel system fuse/relay.

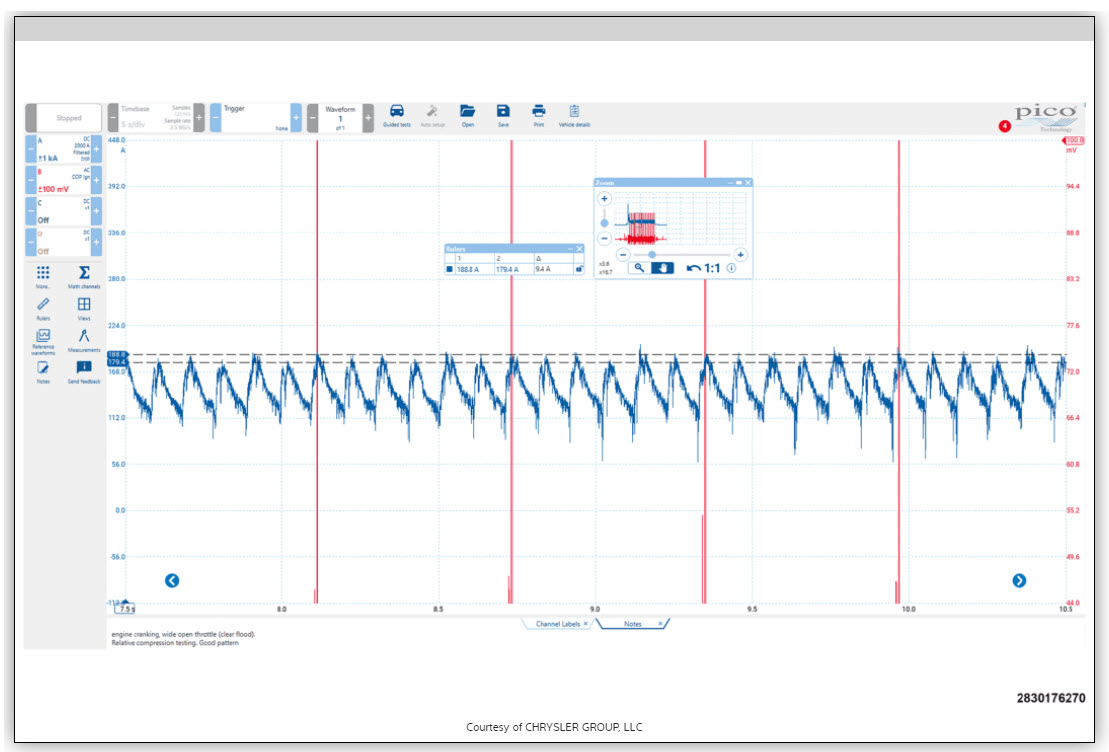

On engines with good compression across all cylinders, the amperage peaks will all be relatively equal. However on an engine with compression issues the starter current draw will be visibly lower on the graph.

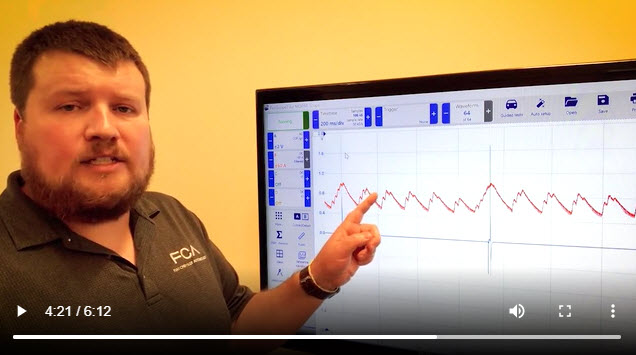

We have a video available in ProDemand auto repair information (for current ProDemand customers) for the 2021 Challenger which can be found if you search for “compression test” and click on the “OEM Testing” card.

Take a look at the examples below to help visualize the outcome you want to achieve.

Figure 1: Example graph of an engine with good compression across all cylinders:

Figure 2: Example graph of with low compression on cylinder one:

Want to learn more about ProDemand?

Request a FREE DEMO!