Your customer comes into your shop needing new brakes on their vehicle. After a few hours working on the vehicle, replacing the brake pads, shaving the rotors, placing the tires back on and making sure the alignment is correct, you are done with the job right?

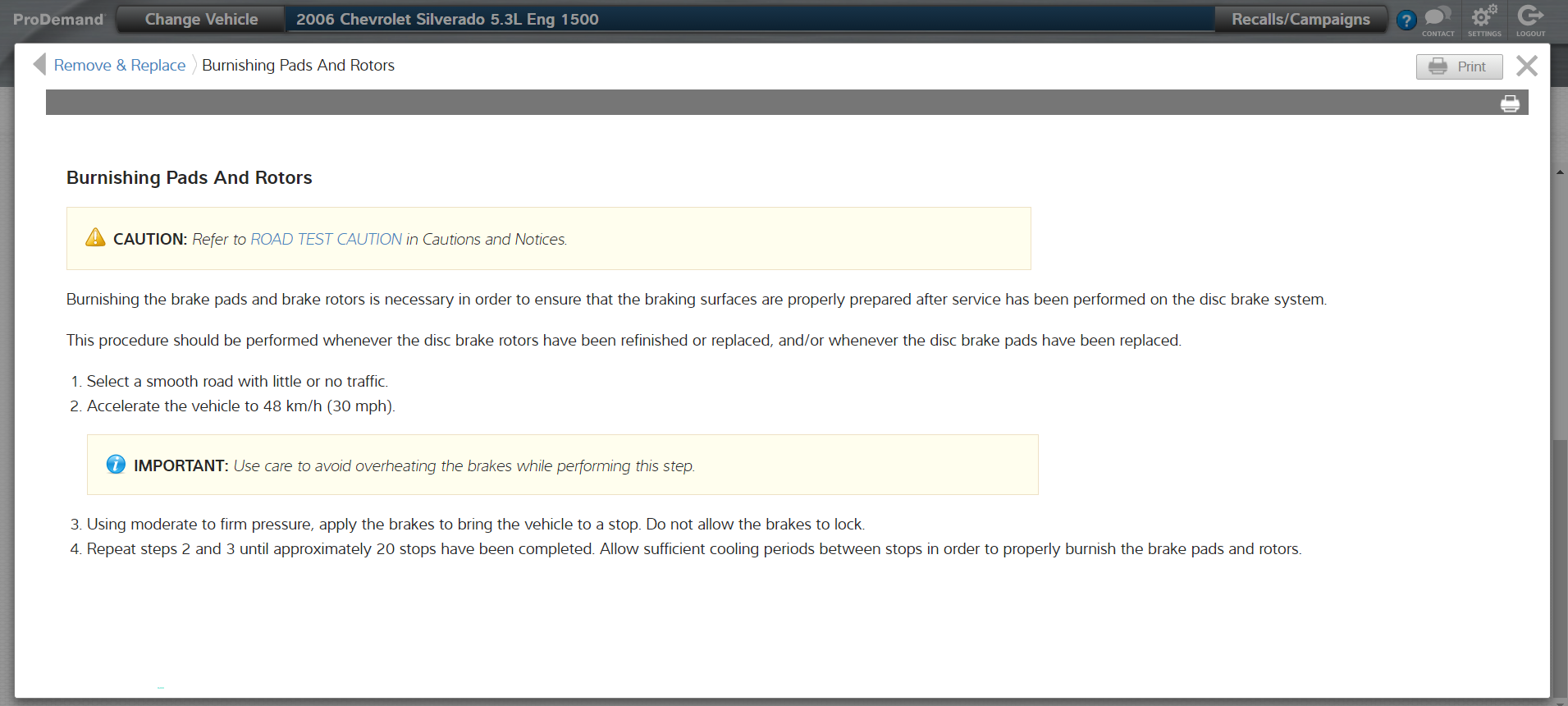

Not exactly. Technicians know that new brakes need “breaking in” to be truly safe for driving. It’s about driving the vehicle and making several stops to get the new pads and resurfaced/replaced rotors acquainted. This is normally done with a process known as the BURNISH CYCLE, where a vehicle is started and stopped about 200 times, at a speed of about 30 mph.

While this process is simple enough, the time it takes a technician to do 200 stop-and-go’s would not be practical and your customers wouldn’t be too happy to pay the hourly rate for doing this task. Why not take your shop’s customer service up a notch with a faster yet sufficient burnishing cycle that any shop can do.

Below are two effective burnish cycle programs that are recommended as sufficient and time efficient for auto shops to perform for their customers.

Option 1

- Make approximately 20 safe “Complete Stops” from 30 mph.

Option 2

- 20 “Slow-Downs” from 50 mph to 20 mph with light to moderate pedal pressure

- No panic stops!

- -Allow at least 30 seconds between brake applications for the brake pads or shoes to cool down

- It is critical to follow cool down procedures to avoid damaging NAO, Ceramic and Semi-Met friction material as well as the rotor/drum

- No high-speed stops and/or braking under heavy loads that could result in glazed or otherwise damaged linings

You’ll see brake burnishing procedures in ProDemand auto repair information software, including the labor times when writing an estimate.

Want to learn more about ProDemand?

Request a FREE DEMO!

ALSO READ: