We regularly get customer feedback from many different sources, and we welcome all of it as it helps guide us as we continually develop and improve our software.

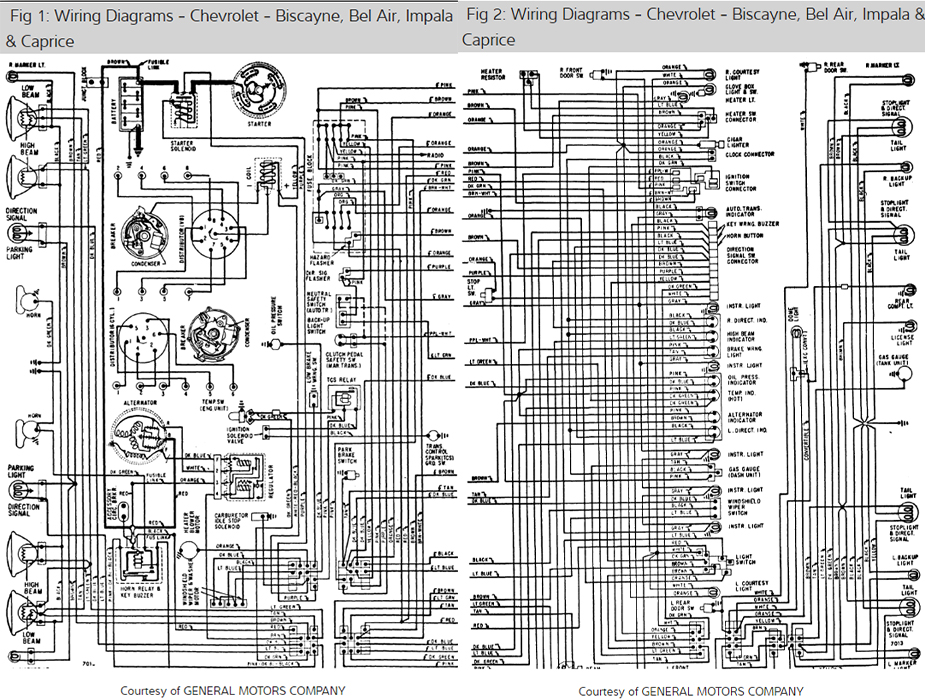

Recently someone commented on the Mitchell 1 Facebook page, with a question about the wiring diagrams in ProDemand auto repair information. He wanted to know why we can’t show ALL of the wiring on a modern vehicle in a single image like we used to be able to do. To answer the question, I’m going to use a 1970 Chevy Impala and a 2016 Chevy Impala as examples.

Let’s look at the 1970 Impala. The first thing you notice is that the whole vehicle’s wiring fits on two pages – bumper to bumper – Body, Ignition (both 6 & 8 cylinder), Charging, HVAC — all on two pages. Things were pretty simple back then.

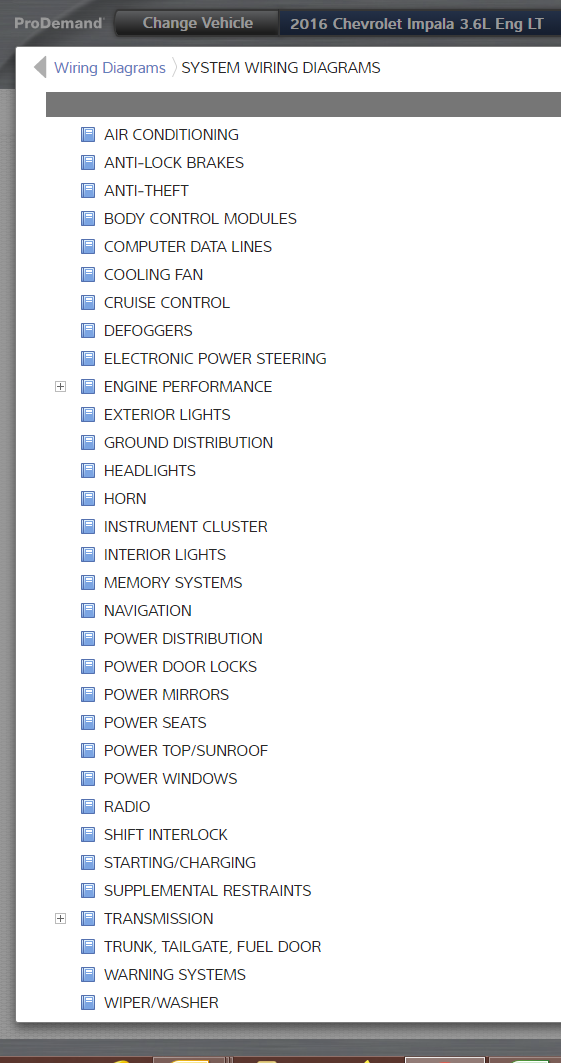

Now let’s look at the 2016 Chevy Impala. Sadly, no more V8s. No mechanical fuel pump or window crank handles either.

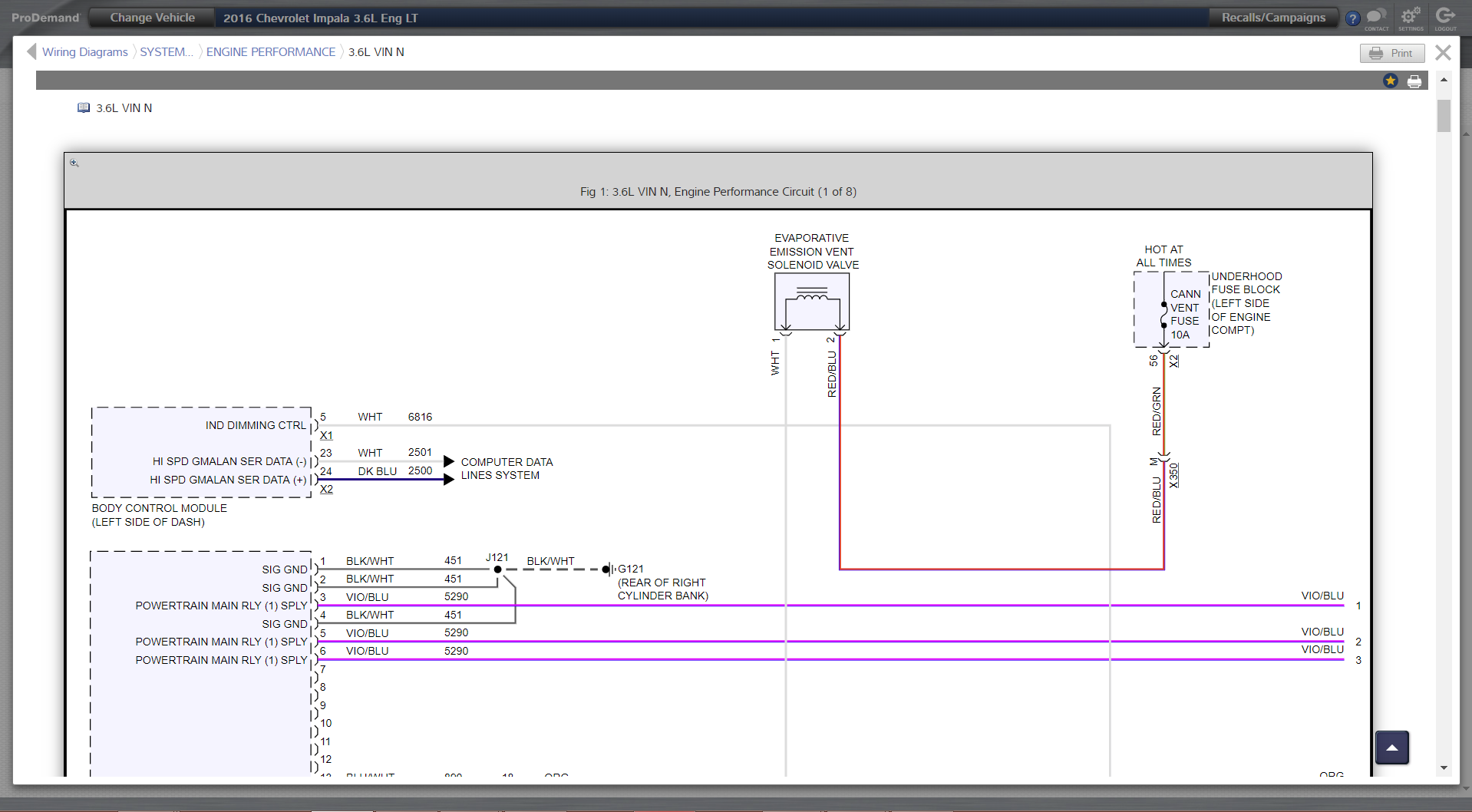

Let’s first look at a list of the systems that are on a modern version of this vehicle that make up the electrical system. There are over 30 sub-systems that make up the vehicle’s complete electrical system. If we look at the Engine Performance wiring it now takes eight diagrams to show everything: APP Sensor, CKP and CMP Sensors, O2 Sensors, Fuel Injectors, Ignition Coils. Over 60 components in all. The AC system has four diagrams. The Anti-theft has four diagrams as well. Supplemental Restraints has three diagrams. There’s no way to fit everything on two pages any more.

The ProDemand wiring diagrams are made up of single images that are grouped together by systems. We’ve done almost all that we can to provide some form of continuity across the set of diagrams by highlighting traces within a system on the vehicle.

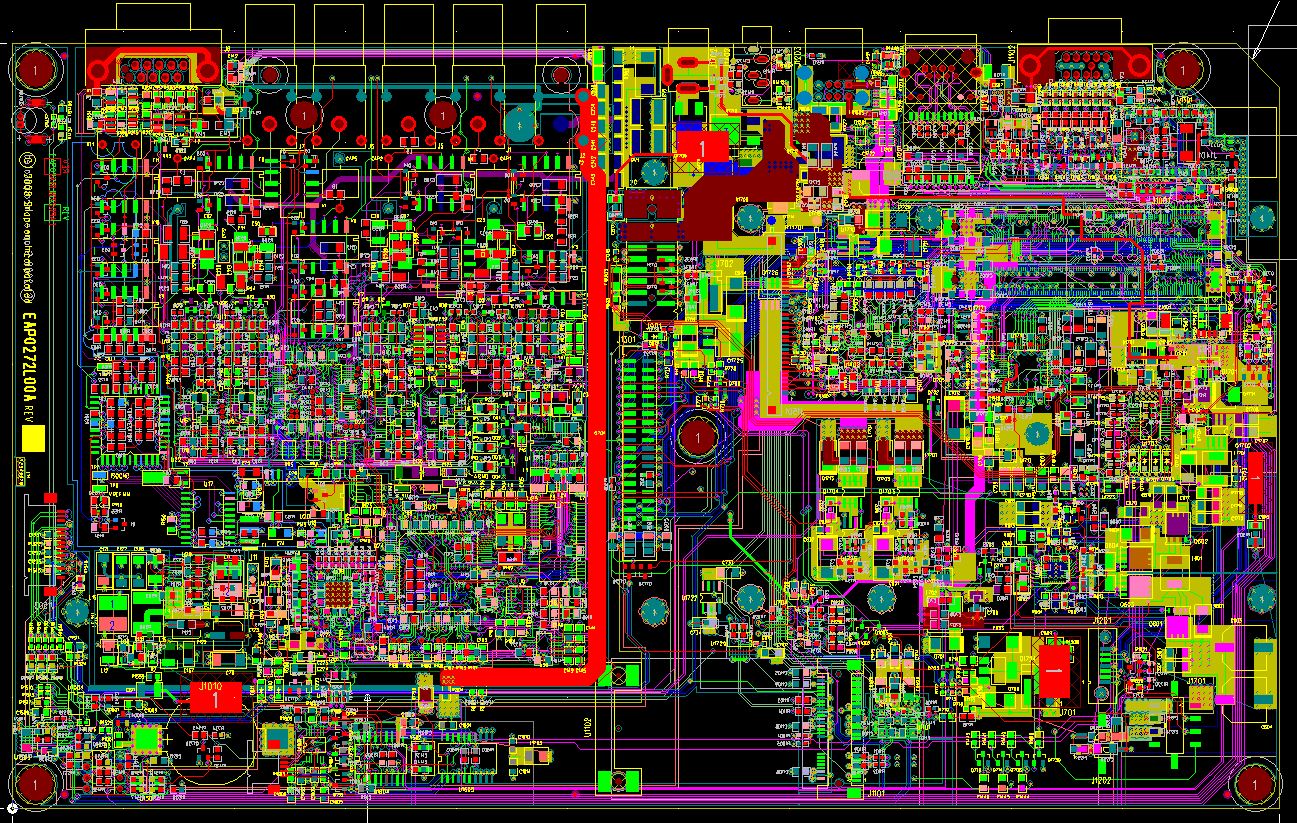

Cars of old had very simple electrical systems and we could easily fit everything on one or two pages. Today’s vehicles are more complex and subsequently require us to break things out by systems or the diagrams would be so cluttered that you couldn’t use them.

The best example that I can come up with to illustrate this is a multi-layer PC board. The image shown below is the eight-layer board of a Snap-on Verus diagnostic platform. Imagine that every layer is a separate system on a vehicle. Looking at each layer (vehicle system) individually would be relatively easy compared to looking at all the layers combined (the whole car). This image shows the “super-imposed” view — a mash-up—of all eight layers. It is very complex and difficult to follow an individual trace. The same could be said if all of a vehicle’s systems were on one or two pages.

This does make being a technician today much harder than that of a tech 30+ years ago. Today’s Techs need to understand that systems that were once exclusive can now be dependent on and/or interactive with other systems because of the modern CAN (Controlled Area Network) systems on these vehicles. There are many systems on today’s cars that rely upon another system’s parameters to operate as designed. ADAS-capable vehicles are a perfect example, and as we transition to fully autonomous self-driving vehicles this dependency will be even greater.

Today’s vehicles are becoming more and more complex and the diagnosis and repair of them is even more challenging. This requires techs to be able to think like a car’s computer “command center” instead of a car’s individual systems.

Here at Mitchell 1, we will continue to do all that we can to help service professionals meet these challenges in an ever- changing industry.