In my days in the shop when we needed to charge a battery you hooked up the charger ran it on high for 20 minutes then went on with your repair. Today’s trucks require a fully charged battery to power the engine along with all the added accessories. Let’s take a look at what is required to correctly charge a battery.

The time required to charge a battery will vary, depending upon the following factors:

- Battery Capacity – A completely discharged heavy-duty battery requires twice the charging time of a small capacity battery.

- Temperature – A longer time will be needed to charge a battery at -18 degrees C (0 degrees F) than at 27 degrees C (80 degrees F). When a fast battery charger is connected to a cold battery, the current accepted by the battery will be very low at first. As the battery warms, it will accept a higher charging current rate (amperage).

- Charger Capacity – A battery charger that supplies only five amperes will require a longer charging time. A battery charger that supplies twenty amperes or more will require a shorter charging time.

- State-Of-Charge – A completely discharged battery requires more charging time than a partially discharged battery. Electrolyte is nearly pure water in a completely discharged battery. At first, the charging current (amperage) will be low. As the battery charges, the specific gravity of the electrolyte will gradually rise.

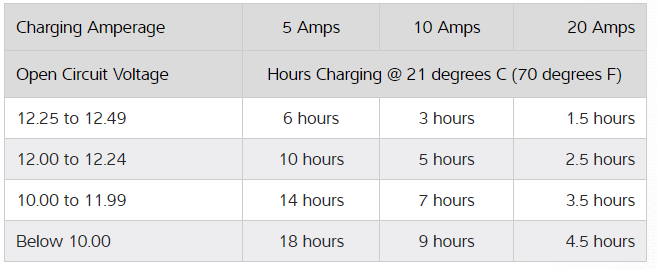

The Battery Charging Time Table gives an indication of the time required to charge a typical battery at room temperature based upon the battery state-of-charge and the charger capacity.

- If testing the battery OUT-OF-VEHICLE, clean the battery terminals with a wire brush before testing.

- If testing the battery IN-THE-VEHICLE, make certain all vehicle accessory loads are OFF, including the ignition.

TruckSeries provides information for many vehicles including procedures for testing battery voltage, load testing, voltage drop test, removal and installation procedures along with battery cable torque specifications. Yes, many OEM’s now provide torque specifications for tightening battery cables and ground strap bolts. With all this information just a mouse click away take advantage and ensure your battery is fully charged and correctly installed. Every electrical component requires a fully charged battery to complete its function. Use the information provided to ensure your job is completed right the first time, help prevent a possible come-back and get that truck back on the road!