As features enhancing comfortability continue, the various vehicle systems may not always function together as expected. Thus, understanding the inner workings becomes helpful to identify and resolve potential problems. Learn how everyday examples with simple and practical explanations go a long way in solving diagnostic issues.

As features enhancing comfortability continue, the various vehicle systems may not always function together as expected. Thus, understanding the inner workings becomes helpful to identify and resolve potential problems. Learn how everyday examples with simple and practical explanations go a long way in solving diagnostic issues.

Navigating the Challenges of Vehicle Repairs

Truck technicians face unique challenges in resolving vehicle concerns. The phantom fix syndrome promotes false testing results, and finding accurate solutions can be complex. Discover common causes and how following solid testing procedures can save time and ensure accurate repairs.

Truck technicians face unique challenges in resolving vehicle concerns. The phantom fix syndrome promotes false testing results, and finding accurate solutions can be complex. Discover common causes and how following solid testing procedures can save time and ensure accurate repairs.

Maximizing Truck Maintenance Efficiency – FREE Downloadable White Paper!

Leverage online access to ATA’s TMC Recommended Practices directly through TruckSeries, to maximize your shop’s efficiency. In this white paper, discover the crucial role of TMC RPs in the industry; providing standardized procedures and best practices for truck maintenance and repair.

Leverage online access to ATA’s TMC Recommended Practices directly through TruckSeries, to maximize your shop’s efficiency. In this white paper, discover the crucial role of TMC RPs in the industry; providing standardized procedures and best practices for truck maintenance and repair.

FREE TruckSeries White Paper ➤

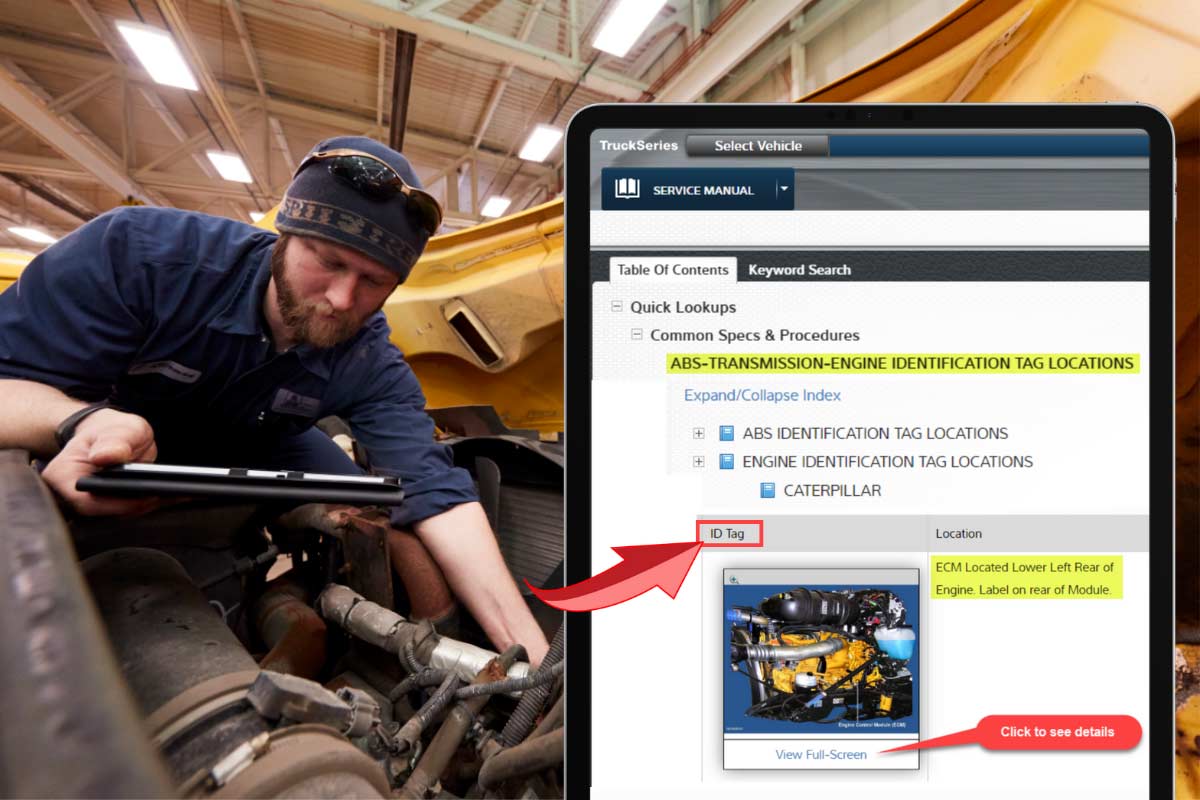

Mitchell 1 Enhances TruckSeries with Quick ABS, Engine, and Transmission Identification

Introducing the latest enhancements to TruckSeries, designed to streamline truck diagnosis and repair. With Quick ABS, Engine, and Transmission Identification, this new feature assists technicians in locating and recognizing crucial identification tags. Learn how to utilize this new feature and save valuable time in the shop to ultimately boost revenue and productivity! ➤

Introducing the latest enhancements to TruckSeries, designed to streamline truck diagnosis and repair. With Quick ABS, Engine, and Transmission Identification, this new feature assists technicians in locating and recognizing crucial identification tags. Learn how to utilize this new feature and save valuable time in the shop to ultimately boost revenue and productivity! ➤

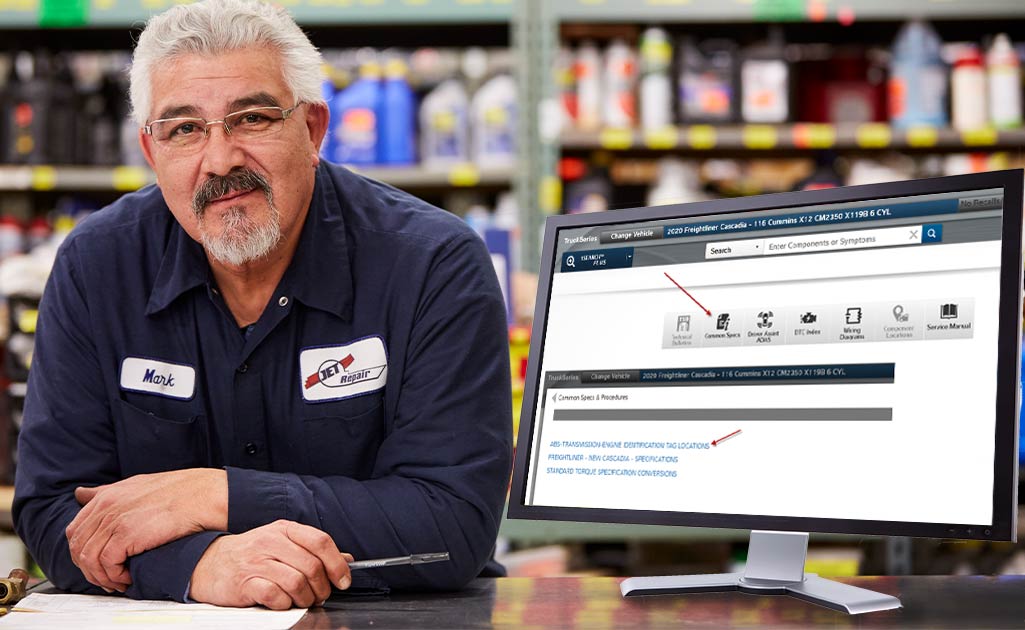

TMC Recommended Practices Are a Click Away in TruckSeries

We understand the importance of staying up-to-date with the best repair methods for truck maintenance. That’s why Mitchell 1 offers easy access to the Technology and Maintenance Council’s (TMC) Recommended Practices (RPs) in our TruckSeries application. In this blog, find two ways to access these practices with a quick how-to, walk-through.

We understand the importance of staying up-to-date with the best repair methods for truck maintenance. That’s why Mitchell 1 offers easy access to the Technology and Maintenance Council’s (TMC) Recommended Practices (RPs) in our TruckSeries application. In this blog, find two ways to access these practices with a quick how-to, walk-through.

TruckSeries Adds ID Tags to Simplify Identification and Location of Control Modules

In this blog, discover a useful new feature designed to help TruckSeries users easily identify and locate control modules for ABS, Engine and Transmission systems. Read on to learn how to access the NEW ID tag identification and location feature through 1Search Plus and the Service Manual, with a step-by-step guide.

In this blog, discover a useful new feature designed to help TruckSeries users easily identify and locate control modules for ABS, Engine and Transmission systems. Read on to learn how to access the NEW ID tag identification and location feature through 1Search Plus and the Service Manual, with a step-by-step guide.

Slowing Down for Accurate Electrical Diagnoses: The Importance of Preliminary Testing

Efficiency is key to successful shop operation, but the pressure to save time and effort can compromise accuracy. Technicians must resist the temptation of jumping to conclusions, which can lead to misdiagnosis and wasted time. Attention to detail is essential for enhancing shop efficiency.

Efficiency is key to successful shop operation, but the pressure to save time and effort can compromise accuracy. Technicians must resist the temptation of jumping to conclusions, which can lead to misdiagnosis and wasted time. Attention to detail is essential for enhancing shop efficiency.

A Little Truck Maintenance Prep Can Go a Long Way

Jake Schell shares his experience with changing the oil of an old 1967 Mack cabover truck. The blog reveals the importance of preparation and attention to detail in successfully maintaining trucks, particularly in today’s trucking industry, where vehicles are significantly more complex.

Jake Schell shares his experience with changing the oil of an old 1967 Mack cabover truck. The blog reveals the importance of preparation and attention to detail in successfully maintaining trucks, particularly in today’s trucking industry, where vehicles are significantly more complex.

When Gravity Can Let You Down

There are numerous components on a truck that hold potential energy. Take for instance, a driveshaft, which can be suddenly converted to kinetic energy and become a hazard if it’s not removed with caution. Learn more in Jake Schell’s monthly column published in Fleet Equipment magazine.

There are numerous components on a truck that hold potential energy. Take for instance, a driveshaft, which can be suddenly converted to kinetic energy and become a hazard if it’s not removed with caution. Learn more in Jake Schell’s monthly column published in Fleet Equipment magazine.

The 3 Key Elements that Drive Shop Safety

In a fast-paced and hazardous shop environment, overlooking even the smallest details can have severe consequences. In this blog post, our very own Jack Schell explores three key elements that can help keep you and others safe at the shop.

In a fast-paced and hazardous shop environment, overlooking even the smallest details can have severe consequences. In this blog post, our very own Jack Schell explores three key elements that can help keep you and others safe at the shop.