John L. Prinvale: Nurturing Automotive Information through Generations

Editor’s Note: This is Part 3 of a history series tracing the evolution of Mitchell 1 and individuals who have contributed to the company’s success for over a century.

The rich history of Mitchell 1 extends far beyond the origins of Samuel Payne Reed developing the Reed Service Manual or Glenn Mitchell’s early garage assemblies. The success of Mitchell 1 is deeply rooted in the dedication of countless individuals who, for over a century, have contributed their unique skills and knowledge to create a comprehensive, user-friendly storehouse of automotive information and insight.

A Legacy of Commitment

The company’s success is rooted in the commitment of shop owners, managers, service writers, parts salespeople and technicians who recognize the value of Mitchell 1 products in meeting their everyday challenge of providing accurate, fast and efficient service.

Focus on Service Personnel

John & his wife, Laurine, at AAPEX 2023

John L. Prinvale: A Lifetime in Automotive Service

With a focus on the role service personnel play in Mitchell 1’s history, we turn to the reminiscences and ongoing experiences of John L. Prinvale, who boasts nearly half a century in the automotive service industry.

At age 75, John demonstrates an undiminishing passion for all things mechanical and continued learning. “Bring it to the door and I will work on it!” John energetically exclaims. John, who with his wife, Laurine, will celebrate their 50th wedding anniversary next year, has made a good life and raised two daughters while operating his independent shop, John’s Automotive Electrical Specialist.

From Childhood Curiosity to Expertise

As with many entering the automotive service industry, John started tinkering with bicycles, lawnmowers, and other things mechanical in his childhood. John said, “When I was a kid, I wanted to know how things work, and that desire never stopped.”

John explained, “The desire to understand what is going on inside a thing often resulted in dismantled objects scattered on the floor waiting to eventually make their way to the trash bin.” For a few of us, like John, these destructive teardowns eventually led to a better understanding of how things function, including the intricate systems within a car.

This writer remembers when his dad demonstrated how the parts in a bicycle coaster brake functioned to stop the bicycle. Gaining that wisdom was a revelation and began forming the groundwork toward understanding how mechanical objects work in conjunction with each other. A car is, after all, a single machine made up of many systems wherein other sub-systems operate through interacting parts.

John’s mechanical interest extended to the laundry and dry-cleaning machine business his father operated. John learned how to repair and maintain laundry machines as well as the delivery vehicles used in the business. “I got a taste of working on about everything with that job but I had not settled into anything focused in the field,” John tells of those early days.

Venturing into Electronics

In 1968, John L. Prinvale started working as an apprentice at a Volkswagen shop in Belmont, California. Then a stint in the U.S. Army from 1969-1972 briefly put John’s career on hold. However, after his return from the Army, John was encouraged by a friend of his father from the laundry machine business to explore the electronics field. From that encouragement, John ultimately opened his own automotive repair shop in 1977.

In 1968, John L. Prinvale started working as an apprentice at a Volkswagen shop in Belmont, California. Then a stint in the U.S. Army from 1969-1972 briefly put John’s career on hold. However, after his return from the Army, John was encouraged by a friend of his father from the laundry machine business to explore the electronics field. From that encouragement, John ultimately opened his own automotive repair shop in 1977.

John initially opened a full-service repair shop and did well. However, his growing interest in electronics led him to enroll in a Motorcraft electronics correspondence course in 1980.

John explains how during this course, he discovered a vital element for electrical diagnosis and repair: “I absorbed the formula for OHMs Law and was then able to move forward with my understanding of how electricity works.” This newfound insight into electronics prompted John to shift his shop’s focus entirely to electrical diagnostics in 1982.

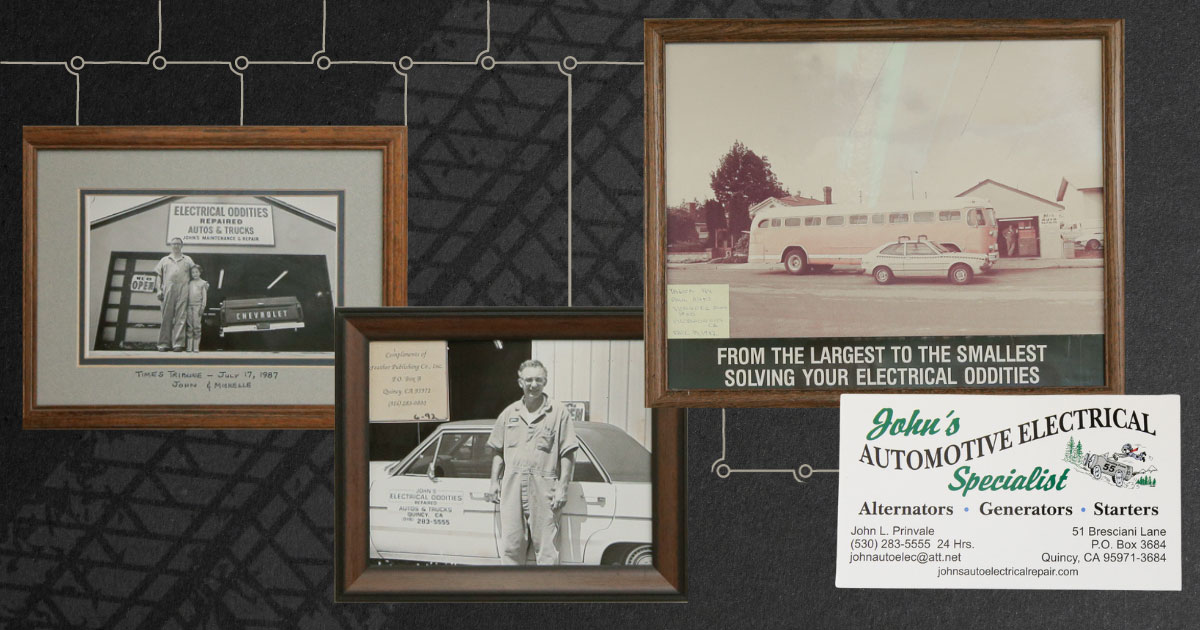

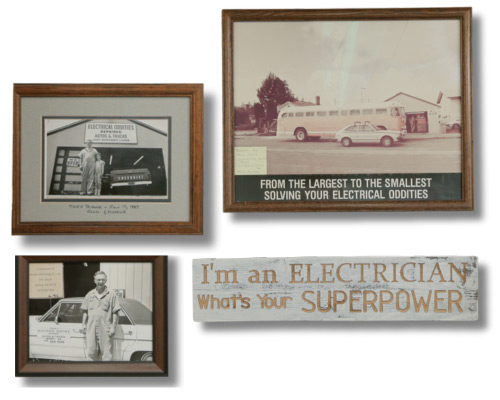

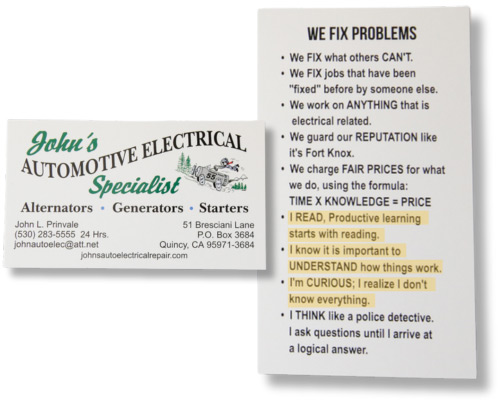

John’s Business Card

John’s ability to comprehend the intricacies of electrical systems allowed him to better understand the reasons behind system failures. This expertise attracted other shops to seek John’s assistance for their electrical diagnoses.

John makes some great points about learning and being successful on the back of his business card:

- I READ, Productive learning starts with reading.

- I know it is important to UNDERSTAND how things work.

- I’m CURIOUS: I realize I don’t know everything.

Learning from Challenges

During our interview, John offered some great insight into learning and taking advantage of experience. John became frustrated with the alternators and starters that were failing. John explains, “I decided to dig in and find out what was causing the various failures and what could be done to correct the issues.” It took a considerable amount of time to identify those issues and implement solutions, time that was essentially lost revenue to his shop if he had ended there.

John’s Certifications

John adds, “I took the know-how gained from learning what caused the failures and began rebuilding alternators and starters as part of my business.” This approach to learning, John continues to employ in his shop today. Taking the time to understand how all the components of a system function has served John well in providing accurate repairs that make his shop successful.

John agreed, that learning how something works in the initial stages is akin to a piggybank that collects interest, and each addition pays off with future jobs. John pointed out, “I am starting to work on the busses for the school, and I need to learn about the CAN network to be able to fix them, so I signed up for a class on CAN networks.”

John again added the admonitions, “Never stop being curious and never stop learning.” Fantastic advice at any age or in any industry.

Mitchell 1’s Contribution to Success

Mitchell 1 also played a key role in John’s success, as he considers their products the best service information available. John says, “The service information is easy to use and provides the knowledge needed to understand complex systems.” In addition, John conveyed how “The Mitchell 1 support team supplies excellent service in helping me when more information is needed.”

John particularly values Mitchell 1 wiring diagrams, which have been immensely helpful in learning how specific electrical systems work. More importantly, he noted that Mitchell 1 wiring diagrams keep getting better with additional features that make tracing circuits simple.

“The ability to highlight a circuit, search for components, and link out to additional information to better understand how the system works make Mitchell 1 wiring diagrams the best value going,” he said.

Enhancing Shop Performance

When asked about Mitchell 1’s impact on his shop’s performance, John emphasizes, “A lack of information equals a lack of production.” Reflecting on the evolution of shop time allocation, he notes that accurate and easy-to-use service information is vital for success, especially with today’s more complex systems.

As John adds, “I may not know how to do something, but I know where to go look for it. How does it work? You need to know that to fix it. Always remember, productive learning starts with reading and studying.”

John’s commitment to learning is evident in his ongoing use of Mitchell 1 products and his collection of old Mitchell Manuals, Reed Service Manuals, and textbooks by Samuel Payne Reed. John agrees that even though the oldest books are a century old, their basic electronic principles continue to be valid and provide valuable insight for gaining basic diagnostic skills.

John’s vast collection of Mitchell Manuals

In being part of Mitchell 1’s more than a century history, John L. Prinvale is not alone. Thousands of automotive service workers, relying on Mitchell 1, share in its legacy. Everyone at Mitchell 1 takes pride in providing innovative shop service programs and service information, building on the vision that knowledge is the key to success held by Samuel Payne Reed and Glenn Mitchell.