Reduce Downtime with Proper DPF Maintenance

Proper preventive maintenance of the Diesel Particulate Filter (DPF) plays a key role in keeping commercial vehicles up and running. Fleet managers now schedule DPF cleaning as part of regular maintenance. The result is less downtime and fewer unexpected DPF service surprises.

The DPF is a component designed to capture and trap soot and ash produced during diesel engine combustion. It is part of a network of aftertreatment components that work together to clean and treat diesel exhaust emissions. The DPF was introduced as part of EPA 07 emission regulations, followed by EPA 10 emission regulations with the addition of the Selective Catalyst Reduction (SCR) system.

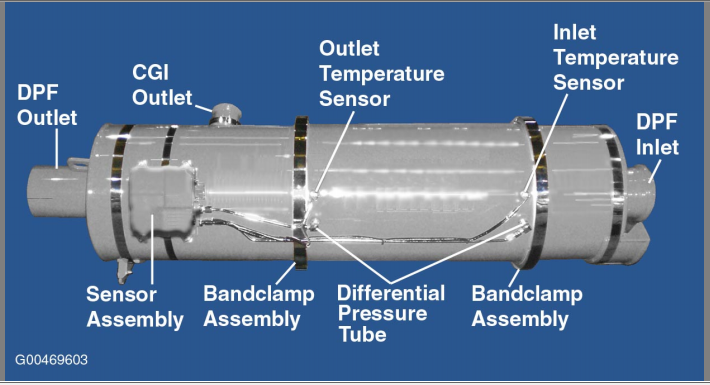

Similar to a muffler in appearance, the DPF is a cylindrical device that has a serviceable filter insert. Figure 1 shows a typical DPF and the various electrical components that are attached to its housing (as seen in Truck Series, Mitchell 1’s truck repair information software).

DPF Cleaning Strategies

The aftertreatment system measures exhaust backpressure and temperatures to calculate the levels of soot and ash on the surface of the DPF. If the DPF system determines it is time for cleaning, it has two strategies: passive and active regeneration. The former is carried out while the vehicle is in operation (without the driver’s knowledge), and the latter is indicated by a light on the dash and requires the truck driver to park the truck and manually switch the regeneration on….and then wait.

Both strategies inject diesel fuel into the inlet of the DPF while using heat generated by the engine exhaust to burn off the soot. The DPF cannot perform as required if the upstream engine systems are not in perfect working order.

Issues like faulty injectors, internal engine oil leaks or internal coolant leaks can cause severe damage to the DPF that requires replacement of the filter. These faults can also be masked by the DPF and may remain undetected until the DPF fails.

To identify upstream faults, it’s important to remove the DPF for inspection and check exhaust opacity in front of the DPF. Also, external damage to the DPF housing or any of the components may compromise the filter’s structural integrity.

Preventive Maintenance Tips

So why, under normal conditions, would the DPF need to be serviced by a technician? While the above mentioned strategies remove the soot from the DPF, the trapped metal oxide ash deposits on the DPF filter need to be physically removed. These ash deposits have been identified as hazardous materials, and due to EPA regulations the service is done in a controlled environment with special machinery designed to clean and capture the remaining deposits.

It is important to note that the use of a pressure washer or compressed air to clean the DPF will cause damage to the filter and should be avoided. The technician should always refer to the DPF supplier’s service recommendation and follow local state and federal regulations when servicing or replacing the DPF. A typical DPF maintenance interval is shown in Figure 2 (from Mitchell 1 TruckSeries).

To get the most out of the DPF system, follow the truck manufacturer maintenance schedules and make sure the DPF system is functioning without any problems. Driver awareness can play a key role in predicting life expectancy of the DPF. Frequent active regeneration events indicate the DPF system is working extra hard to remove the deposits.

Overall, the DPF’s design has improved dramatically after several years of real-world testing. They are lighter, more durable, efficient, and reliable — all of which should contribute to making the truck run more efficiently when properly maintained.

Read More:

- TruckSeries: Repair information for all makes commercial trucks

- Stationary Regeneration – We’ve Got You Covered